Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

As industries strive for greater efficiency and performance, the diaphragm press technology continues to play a pivotal role, especially in sectors such as food processing, pharmaceuticals, and chemical manufacturing. According to the latest market report by Global Industry Analysts, the diaphragm press market is expected to witness significant growth, projecting a compound annual growth rate (CAGR) of 6.5% through 2025. This represents a compelling opportunity for manufacturers and engineers aiming to enhance the operational capabilities of their production lines.

Industry expert Dr. Emily Harrington, a leading authority in fluid mechanics, emphasizes the importance of innovation in diaphragm press technology: "The future of diaphragm presses is not just about optimization; it’s about integrating advanced materials and automation to increase throughput and maintain product quality."

By focusing on technological advancements, manufacturers can address challenges such as inefficient operation and high maintenance costs, ultimately leading to improved yield and energy savings.

In this context, the 2025 Top Diaphragm Press Innovations for Enhanced Efficiency and Performance highlights the top 10 advancements set to transform the industry. These innovations promise to not only elevate productivity but also to contribute to more sustainable practices within various manufacturing environments, making them essential considerations for any company invested in modernizing their production processes.

As diaphragm presses evolve, the integration of innovative sensor technologies stands at the forefront, revolutionizing real-time monitoring capabilities. These advanced sensors can detect and analyze various parameters such as pressure, temperature, and fluid levels during the pressing process. By providing instant data feedback, operators can swiftly adjust conditions to optimize performance and prevent potential issues, significantly enhancing the efficiency of the diaphragm press operation.

Furthermore, the incorporation of IoT connectivity allows for seamless integration of these sensor technologies into broader automated systems. This connectivity enables remote monitoring and data analysis, facilitating proactive maintenance and reducing downtime. With the ability to track performance metrics in real time, manufacturers can implement data-driven decisions, ultimately leading to improved productivity and reduced operational costs. The synergy of innovative sensor technologies with diaphragm press systems not only streamlines processes but also sets new benchmarks for operational excellence in the industry.

| Innovation | Technology Type | Efficiency Improvement (%) | Performance Metric | Real-Time Monitoring Features |

|---|---|---|---|---|

| Smart Pressure Sensors | Sensor Technology | 15% | Pressure Consistency | Live Pressure Readings, Alerts |

| Automated Flow Control | Control Systems | 20% | Production Speed | Flow Rate Monitoring |

| AI-driven Predictive Maintenance | AI Technology | 25% | Downtime Reduction | Condition Monitoring, Alerts |

| Integrated Data Analytics | Software Solutions | 30% | Overall Equipment Effectiveness | Performance Insights, Dashboard |

| Remote Monitoring Solutions | IoT Technology | 18% | Operational Visibility | Alerts, Data Access Anywhere |

The advancements in material science are pivotal for enhancing the durability and performance of diaphragm components in various industrial applications. Recent studies indicate that the utilization of advanced polymer composites, such as reinforced thermoplastics, can significantly improve tear resistance and fatigue life. According to a report by the International Journal of Material Science, these new materials can increase the lifespan of diaphragm components by up to 30%, thereby reducing the frequency of replacements and maintenance costs for manufacturers.

Furthermore, innovations in the manufacturing process, like 3D printing and precision molding, allow for the production of more complex diaphragm shapes that fit better and function more efficiently. The American Society of Mechanical Engineers highlights that these techniques can enhance performance by up to 25% in specific applications, including aerospace and aeronautics, where high efficiency and durability are crucial. As the industry progresses towards more sustainable practices, the development of bio-based materials also shows great promise in reducing environmental impact while maintaining high performance standards.

The advancement of smart automation solutions in diaphragm press operations marks a significant step toward enhancing efficiency and performance in manufacturing processes. As industries strive for increased productivity, integrating intelligent systems into diaphragm presses allows for real-time monitoring and control. These automation technologies not only optimize production schedules but also ensure consistent quality in product output. With sensors and data analytics, operators can instantly detect deviations and respond proactively, minimizing downtime and waste.

Moreover, smart automation simplifies the complexity of diaphragm press workflows by incorporating user-friendly interfaces and machine learning algorithms. This enhancement enables operators to configure and adjust machine settings effortlessly, ensuring that equipment runs at peak performance. Additionally, the connection of diaphragm presses to broader smart factory ecosystems facilitates seamless communication between machines, allowing for coordinated operations and enhanced resource management. As manufacturers adopt these cutting-edge solutions, they position themselves to meet the growing demands of the market while significantly improving operational efficiency and cost-effectiveness.

The diaphragm press market is undergoing a transformative phase focused on energy efficiency strategies that significantly reduce waste and optimize power usage. According to recent projections, the global pumps market, closely tied to diaphragm press innovations, is expected to reach USD 85.81 billion by 2031, growing at a CAGR of 4.30% from USD 63.92 billion in 2024. This growth highlights the industry's push for advanced technologies that enhance operational efficiency.

Implementing energy-efficient practices in diaphragm presses can lead to substantial cost savings and environmental benefits. Adoption of variable frequency drives (VFDs) is one such strategy, allowing operators to adjust energy consumption based on demand. Additionally, regular maintenance of diaphragm systems ensures optimal performance and reduces energy wastage.

Tips:

Innovations in diaphragm press technology are increasingly focusing on user-centric design features that significantly enhance usability and maintenance for operators in the industry. By incorporating ergonomic interfaces and intuitive controls, manufacturers are ensuring that operators can efficiently manage the complex functions of diaphragm presses without extensive training. Features such as customizable touch panels and real-time performance monitoring simplify the operational process, allowing for quicker adjustments and less downtime.

Moreover, advancements in maintenance accessibility are transforming the operational landscape. Quick-release mechanisms and modular components enable operators to perform routine maintenance tasks with minimal disruption to production schedules. These designs facilitate easier access to critical parts, reducing the time spent on repairs and enhancing overall productivity. By prioritizing user experience, these innovations not only improve the day-to-day functioning of diaphragm presses but also contribute to a safer and more efficient work environment. As the industry evolves, the emphasis on operator usability will continue to drive advancements in technology, making it imperative for manufacturers to focus on these essential features.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

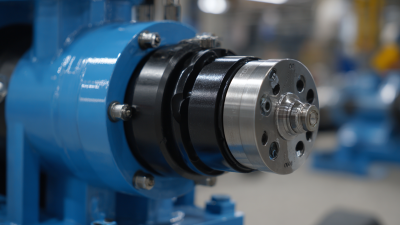

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.