Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

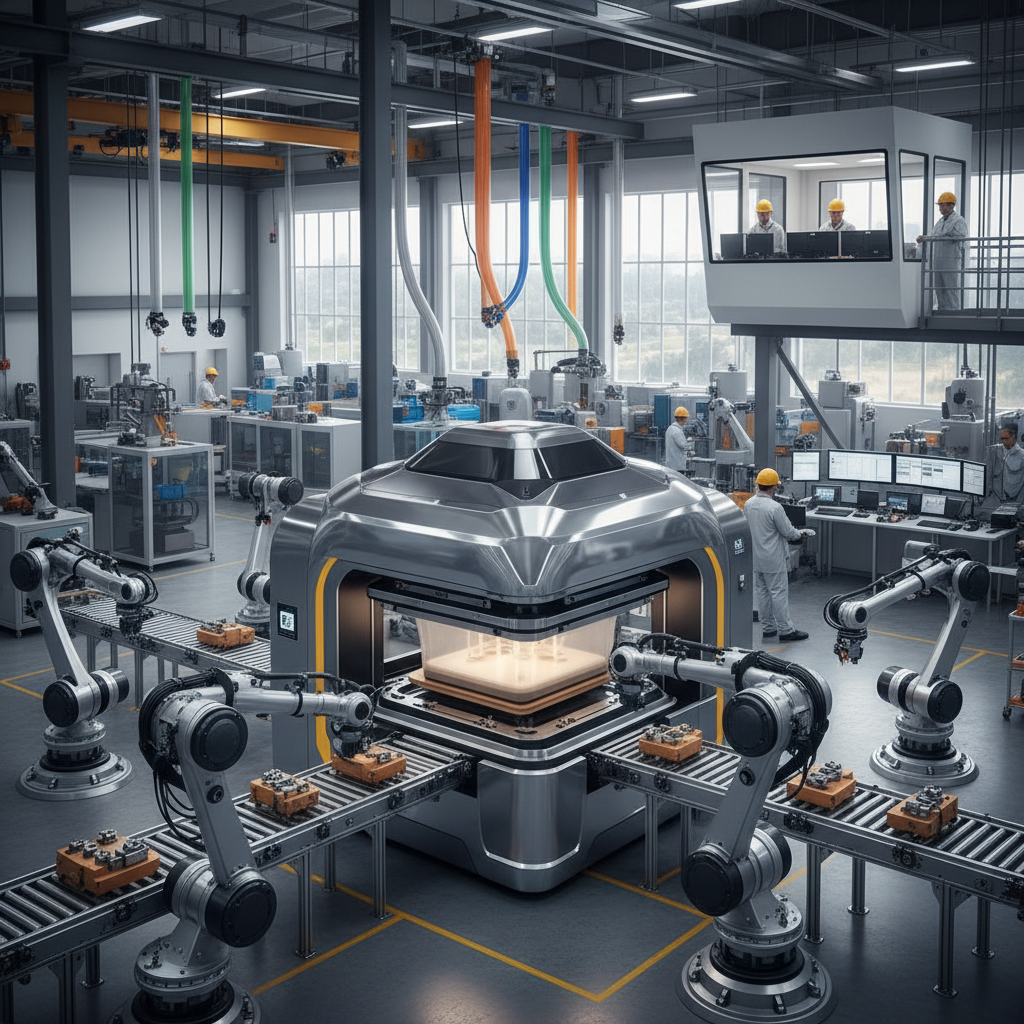

In today's manufacturing landscape, efficiency and precision are paramount. Companies are consistently seeking innovative techniques to enhance production capabilities, and one such solution is the diaphragm press. According to a report by Market Research Future, the global diaphragm press market is projected to witness significant growth, driven by its advantages in optimizing material usage and reducing waste. The diaphragm press is renowned for its ability to produce high-quality outputs with minimal energy consumption, making it an eco-friendly alternative in various applications.

Moreover, data from the International Journal of Advanced Manufacturing Technology indicates that operations utilizing diaphragm presses report an increase in throughput and a decrease in cycle times compared to conventional pressing methods. This technology not only enhances productivity but also allows for more versatile applications across multiple industries, including automotive, aerospace, and consumer goods. As enterprises strive to maintain a competitive edge, understanding the top advantages of incorporating a diaphragm press into production processes becomes essential for sustained growth and operational excellence.

The diaphragm press is rapidly gaining traction in various production industries for its ability to enhance precision and consistency. According to a recent report by Smith & Associates, companies utilizing diaphragm presses reported a 30% increase in product uniformity, significantly reducing defects. The mechanism of the diaphragm allows for a more controlled application of pressure, ensuring materials are evenly compressed, which is crucial for industries such as automotive and electronics where tolerances are tight.

Additionally, improved consistency translates into reduced waste and lower costs. A survey conducted by the Manufacturing Technology Association indicates that businesses that switched to diaphragm presses saw a 20% reduction in raw material usage due to more efficient processing. These enhancements not only bolster product quality but also improve the overall efficiency of production lines.

Tips:

1. Regularly maintain your diaphragm press to optimize performance and prevent inconsistencies that can arise from wear and tear.

2. Train your staff using advanced simulation tools to ensure they understand the optimal settings for different materials.

3. Utilize data analytics to track production quality and adjust parameters in real-time for maximum efficiency.

When it comes to reducing manufacturing expenses, the diaphragm press shines as a cost-effective solution for production needs. This innovative technology utilizes a flexible membrane that evenly distributes pressure, ensuring efficient material usage and minimizing waste. By optimizing the pressing process, manufacturers can achieve higher yields while simultaneously lowering costs associated with raw materials.

Tips to maximize the benefits of diaphragm presses include regular maintenance checks to ensure optimal performance and adhering to proper practices during operation. It’s also beneficial to invest in training for operators, as a skilled workforce can significantly increase productivity and reduce the likelihood of errors, leading to cost savings in the long run. Furthermore, exploring different diaphragm materials can help you find an option that best fits your production needs while staying within budget constraints.

By selecting a diaphragm press, businesses can not only reduce their initial investment but also enhance long-term profitability. The combination of durability and efficiency in these machines makes them a wise choice for manufacturers looking to streamline processes while managing their expenses effectively.

The diaphragm press has emerged as a versatile choice for manufacturers seeking enhanced material compatibility. This equipment is designed to accommodate a variety of materials, making it an ideal solution for diverse applications, ranging from food processing to pharmaceuticals. The unique design allows for gentle yet effective compression, ensuring that sensitive materials maintain their integrity during processing. This adaptability makes diaphragm presses a go-to for industries that require precision and reliability.

Tip: When choosing a diaphragm press, consider the specific properties of the materials you intend to work with. Assess factors like viscosity, temperature sensitivity, and overall composition to ensure optimal performance.

Moreover, diaphragm presses excel in providing consistent results across different materials. Their ability to deliver uniform pressure distribution minimizes the risk of defects in the final product. This feature is particularly beneficial in applications where variations can lead to significant quality concerns. As companies strive for efficiency and cost-effectiveness, embracing the capabilities of diaphragm pressing technology can be a game-changer.

Tip: Regular maintenance and calibration are crucial for maximizing the efficiency of your diaphragm press. Keeping the equipment in top shape ensures that you get the best possible performance across various materials, extending the lifespan of both the press and the products being manufactured.

This bar chart illustrates the top advantages of using a diaphragm press in production. Each advantage is scored based on its significance in application, showcasing the diaphragm press's strengths in enhancing production efficiency.

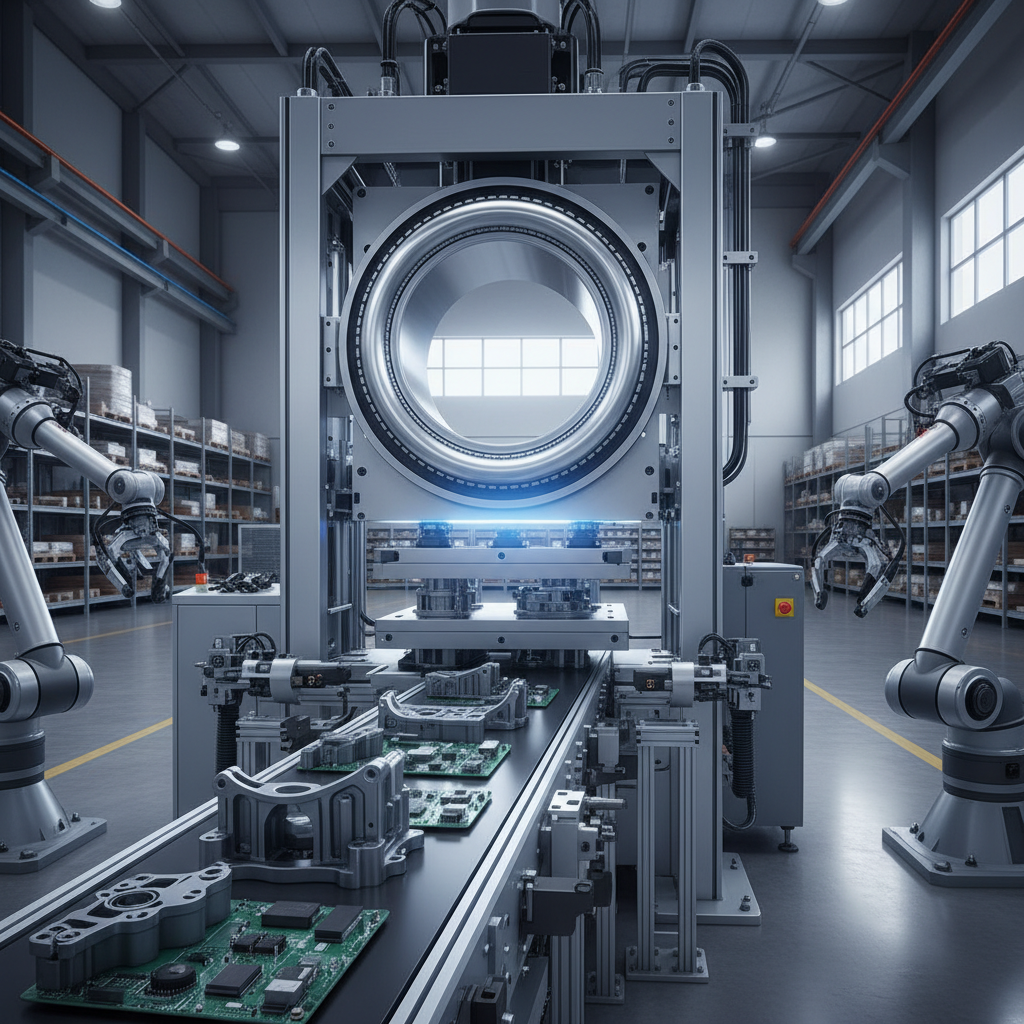

The diaphragm press offers enhanced safety features that significantly benefit operators and the overall production environment.

According to a report by the National Safety Council, workplace injuries account for over 4.6 million incidents annually in the manufacturing sector. Implementing equipment with advanced safety mechanisms, like diaphragm presses, can dramatically reduce these risks.

The diaphragm design minimizes the likelihood of hydraulic failures, a common cause of accidents in traditional presses. Operators are less exposed to hazardous conditions, which not only protects their well-being but also reduces downtime related to safety incidents.

Moreover, diaphragm presses are equipped with superior pressure control systems, which allow for precise adjustments during the production process. A study from the International Journal of Industrial Ergonomics highlights that enhanced ergonomics and operator safety measures can lead to a 25% increase in productivity. By ensuring a safer working environment, companies can maintain a stable workforce and diminish the strain on employees, prompting greater efficiency.

With these factors combined, diaphragm presses serve not only as a reliable production tool but also as a pivotal component for fostering a safe and productive workplace.

Diaphragm presses have gained popularity in various industries due to their remarkable flexibility and customization options. Unlike traditional pressing methods, diaphragm presses can adjust to different materials and production requirements. This adaptability allows manufacturers to create specific configurations and pressure settings tailored to their unique production needs. For instance, whether producing intricate designs or utilizing various material types, diaphragm presses accommodate diverse applications seamlessly, making them a great asset in any production environment.

When considering the implementation of diaphragm presses, it's essential to leverage their customization features effectively. Tips for maximizing their potential include conducting thorough material tests to determine optimal pressure ranges and settings. Additionally, involving your production team in the setup process can uncover insights on how to best utilize the press for specific tasks. Remember, taking the time to understand the capabilities of your diaphragm press will result in higher efficiency and better-quality outputs.

Flexibility is not just about the machine but also about the processes involved. Utilizing interchangeable tooling can further enhance the diaphragm press's capabilities, allowing for quick adjustments during production runs. This versatility means you can switch between jobs with minimal downtime, ultimately boosting your overall productivity and meeting customer demands more promptly.

| Advantage | Description | Application Areas | Flexibility Level |

|---|---|---|---|

| High Compression Force | Able to apply significant forces for material forming. | Metal forming, composite materials. | High |

| Customization Options | Custom molds and shapes can be designed for specific needs. | Bespoke product manufacturing. | Very High |

| Material Versatility | Works with various materials including plastics and metals. | Automotive, aerospace, consumer goods. | Medium |

| Consistent Quality | Produces uniform products with minimal variability. | Mass production environments. | High |

| Energy Efficiency | Uses less energy compared to other pressing methods. | Sustainable production processes. | High |

| Quick Setup Time | Reduced time for mold changes and setup. | Prototyping and small batches. | Very High |

| Compact Design | Space-saving equipment suitable for various layouts. | Small workshops and manufacturing floors. | High |

| User-Friendly Operation | Easier to operate with minimal training required. | General manufacturing operations. | Medium |

| Improved Safety Features | Designed with safety mechanisms to protect operators. | Any production facility. | High |

| Cost-Effective Production | Reduces labor and material costs in the long run. | Large scale manufacturing. | High |

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.