Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

Choosing the right waste water pump can be a daunting task. Different applications require different specifications. Industry expert John Smith, a prominent figure in waste water management, once said, "Selecting a waste water pump should align with specific needs, not general preferences." This advice is crucial for both homeowners and businesses.

Understanding your requirements is essential. Are you managing a small residential system or a large industrial facility? Each situation demands unique considerations. The performance capacity, efficiency, and maintenance requirements all play significant roles. Often, people tend to overlook these details, leading to costly errors.

Let’s face it: many waste water pump buyers rush decisions. They may choose based on price alone or make assumptions about compatibility. Mistakes can arise from inadequate research. It’s vital to evaluate the pump’s features alongside your specific needs. Ignoring this step can cause serious issues. Empowering yourself with knowledge will pave the way for a more informed choice.

When selecting a wastewater pump, it's essential to understand the various types available. Submersible pumps are popular for their underwater application. They can handle large volumes and operate quietly. These pumps excel in deep pits, effortlessly moving wastewater away from your site.

On the other hand, centrifugal pumps are common in many systems. They use rotation to move wastewater, making them efficient for various applications. They work well in standard conditions, but may struggle with solids. Users should be mindful of what they pump. Not every pump suits every method or type of waste.

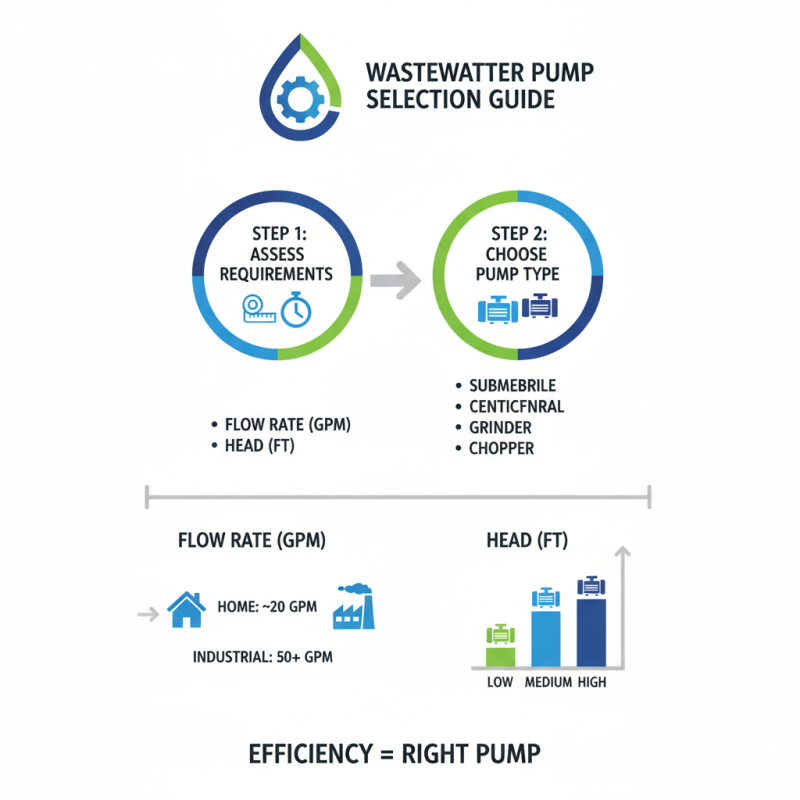

Consider the specifics of your situation. Evaluate the flow rate and head height you need. Each type has strengths and weaknesses, and often the right choice isn't clear. Sometimes, a pump can move more than just water, increasing complexity. Reflect on the potential pitfalls of your choice. Choosing the wrong pump might lead to ineffective results and added costs.

This chart illustrates the various types of waste water pumps and their common applications. The data reflects the percentage of usage among different pump types in waste water management.

When selecting a waste water pump, it is essential to focus on key specifications. These include flow rate, head height, and pump type. The flow rate indicates how much water the pump can move. A higher flow rate may seem better, but too much can lead to problems. Consider your specific needs.

Head height is another crucial factor. This measurement tells you how far the pump can lift water. If your system requires a high lift, you need a pump capable of handling it. Be mindful that oversizing may increase energy costs and wear. Choosing the right pump type is also vital. Submersible pumps excel in various applications, while centrifugal pumps are common for surface water.

Remember the importance of material and durability. Corrosive environments require pumps made of appropriate materials. Take time to reflect on your unique situation. Are your needs short-term or long-term? Assessing all these factors will guide you to a more informed decision.

| Specification | Description | Importance Level |

|---|---|---|

| Pump Type | Submersible, surface, or inline pumps. | High |

| Flow Rate | Measured in gallons per minute (GPM) or liters per second (L/s). | High |

| Head Height | The vertical distance the pump can raise water. | Medium |

| Power Source | Electric, diesel, or solar-powered options. | Medium |

| Pump Material | Cast iron, stainless steel, or thermoplastic materials. | High |

| Noise Level | Measured in decibels (dB), important for residential areas. | Low |

| Automatic Features | Automatic shut-off, float switches, or level sensors. | Medium |

| Warranty and Support | Length of warranty and availability of customer support. | High |

Choosing the right wastewater pump is crucial for efficiency. Understanding flow rate and head requirements is the first step. Flow rate, measured in gallons per minute (GPM), determines how quickly water is moved. Industry standards indicate a typical household may need about 20 GPM. However, higher capacity may be necessary for industrial applications, sometimes exceeding 50 GPM.

Head refers to the vertical distance the pump needs to elevate the water. It is measured in feet. A pump with insufficient head may struggle to deliver water effectively. For example, if a system requires a 30-foot lift, choosing a pump rated below that can lead to significant issues, like reduced performance and increased wear. Research suggests a 10% margin above calculated needs is optimal for longevity.

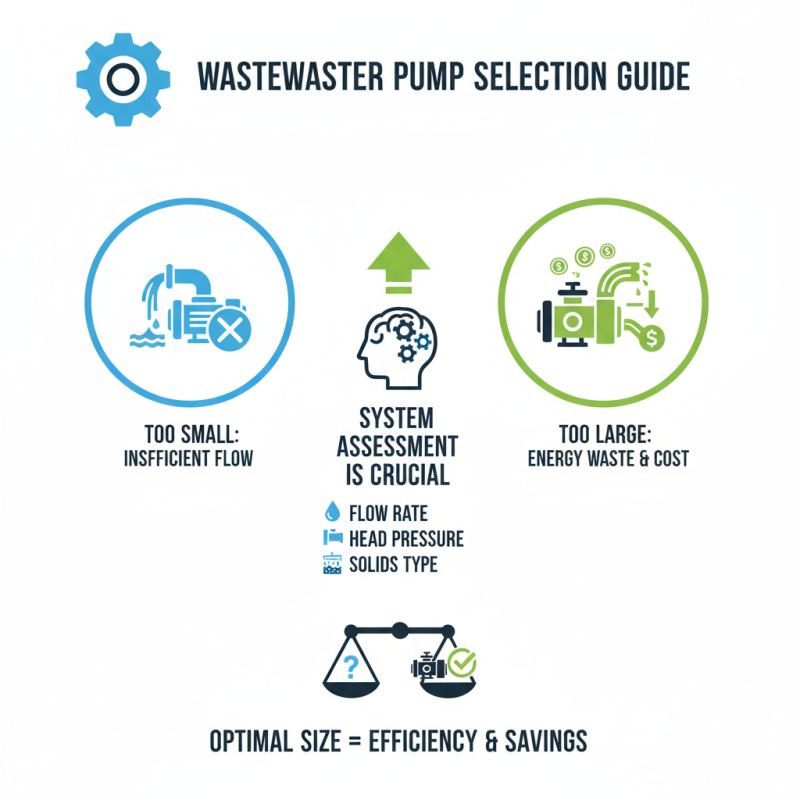

When selecting a pump, consider these parameters carefully. Oversizing can be wasteful. Conversely, undersizing can lead to frequent replacements and system failures. It's essential to calculate accurately and analyze system requirements. Not every situation is straightforward, which may lead users to overlook critical details. Conducting thorough assessments prevents costly mistakes in the long run.

When selecting a waste water pump, evaluating efficiency and energy consumption is crucial. Studies show that pumps can consume up to 80% of total operational costs. Therefore, choosing the right model can significantly cut energy bills. High-efficiency pumps often have a lower total cost of ownership. This means they are not just more efficient but also more economical in the long run.

Look for pumps with a high Energy Efficiency Index (EEI). A good EEI generally falls below 0.4. In fact, it is said that for every 1% improvement in efficiency, energy savings can reach 2-3%. This is not a trivial number, especially for large operations. However, realize that achieving high efficiency might come with complex requirements, including specific installation practices and maintenance schedules.

Understanding your system's needs is essential. Maximum flow rate, total dynamic head, and liquid characteristics play crucial roles. Energy audits can sometimes reveal unexpected inefficiencies in existing systems. This often leads to reflections on past decisions. Perhaps the initial choice lacked consideration for future demands. Don’t overlook the importance of regular monitoring and reassessment. Keep in mind that even the best systems can become less efficient over time without proper maintenance.

Selecting the right wastewater pump can be tricky. One common challenge is determining the correct pump size. If the pump is too small, it won’t handle the flow rate. A pump that is too large may waste energy and lead to increased costs. Assessing the system's requirements accurately is crucial.

Another challenge is understanding the liquid's properties. Wastewater can contain solids, chemicals, and varying temperatures. Each factor affects pump performance. For example, a high solids content might require a heavy-duty design. Careful consideration here is essential to avoid future issues.

Installation can also present obstacles. Tight spaces or challenging access points can complicate the placement of pumps. Inadequate installation may lead to operational failures. Reviewing potential installation sites beforehand can help identify these challenges. Investing time in planning can save headaches later.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.