Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

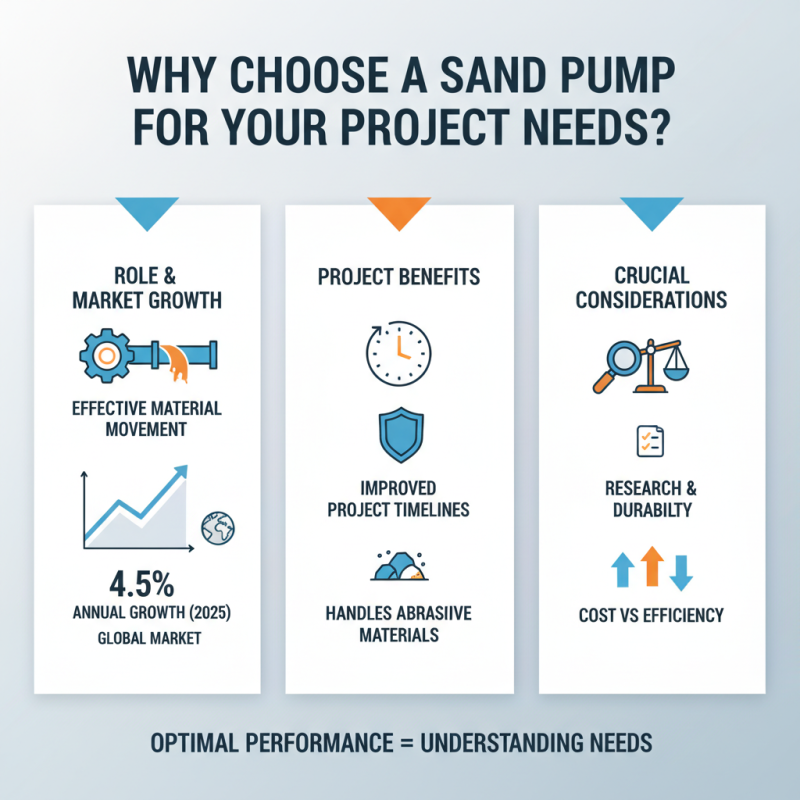

When selecting equipment for a construction or mining project, choosing the right tools is essential. A sand pump plays a crucial role in effectively moving sand and other materials. According to a recent industry report, the global sand pump market is projected to grow by 4.5% annually through 2025. This growth reflects the increasing demand for efficient and reliable pumping solutions.

Using a sand pump can significantly improve project timelines. Its robust design allows it to handle abrasive materials with ease. However, not every sand pump on the market delivers the same performance. Some models may lack durability or have lower flow rates. It’s vital to research and choose a pump that matches your project's specific requirements.

Investing in a high-quality sand pump yields long-term benefits, including reduced operational costs. But this choice should not be taken lightly. As projects vary, assessing the type of material being transported is essential. Balancing cost and efficiency can be challenging, yet necessary for success. Ultimately, understanding your project's needs will guide you towards the right sand pump, ensuring optimal performance.

In the construction and mining industries, a sand pump is an invaluable tool. It efficiently transports sand and slurry across various distances. This efficiency minimizes downtime, enabling projects to move forward. The versatility of sand pumps allows their use in different settings, such as quarries and construction sites. They handle both fine and coarse materials effectively, adapting to changing project needs.

Using a sand pump can significantly enhance productivity. It reduces the physical labor often associated with manual transport. Workers can focus on other critical tasks, increasing overall site efficiency. However, choosing the right pump is essential. An improperly sized pump can lead to frequent maintenance issues. This can hinder operations and raise costs unexpectedly.

Moreover, the environmental impact should not be overlooked. Proper management of pumped materials is necessary to prevent soil erosion and degradation. While sand pumps offer many benefits, awareness of their limitations is crucial. Operators must be trained to maximize the benefits while minimizing potential drawbacks.

Sand pumps are crucial for optimizing material handling processes in various projects. They offer distinct advantages over traditional methods. According to industry data, using sand pumps can increase operational efficiency by up to 30%. This efficiency boost comes from their ability to handle large volumes of material with minimal downtime. The design of these pumps allows for the quick transfer of sand, reducing the delays that often plague manual handling.

In addition, sand pumps minimize material loss during transportation. Research indicates that poorly managed material handling can result in up to 20% waste. Sand pumps mitigate this issue by delivering a more controlled flow and reducing the risk of spillage. Furthermore, they can adapt to various environments, ensuring that project timelines remain intact. However, not all operators are trained adequately, leading to potential operational hitches.

Over time, wear and tear on equipment can also become a concern. Maintenance practices may not keep pace with usage, leading to inefficiencies. These factors highlight the importance of continuous training and regular equipment assessment. In short, while sand pumps significantly enhance operational performance, ongoing vigilance is necessary to realize their full potential.

Sand pumps significantly enhance operational efficiency by optimizing material handling processes. The following bar chart illustrates the average efficiency gains in various project applications when utilizing sand pumps compared to traditional methods.

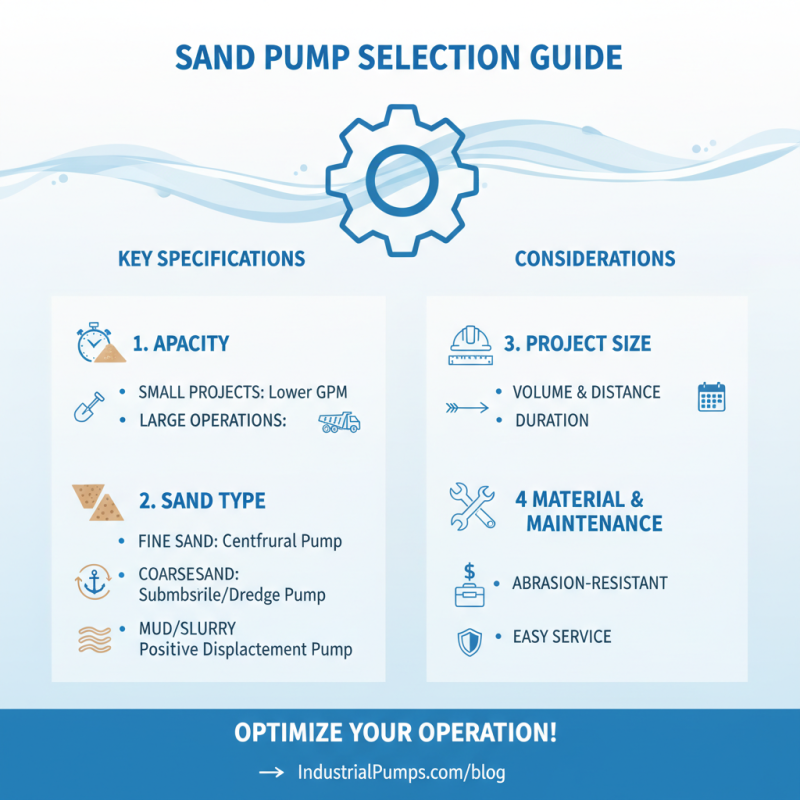

When selecting a sand pump for your project, several key specifications warrant careful consideration. The pump's capacity is crucial. It determines how much sand can be moved within a given time frame. For smaller projects, a lower capacity may suffice. But larger operations need a pump with greater throughput. Also, think about the type of sand you'll be handling. Different sand materials can affect pump performance.

Another vital element is wear resistance. Sand is abrasive, which can lead to increased wear on pump components. Look for pumps that are designed with high-quality materials. This will extend their lifespan. Keep in mind the total dynamic head (TDH) as well. It influences how efficiently the pump can operate over varying distances and heights.

Additionally, reflect on the size and weight of the pump. Larger models may be more challenging to transport and install. You may deal with logistical issues if the pump does not fit your project site. Consider all these factors, and make informed decisions to align with your project needs.

When it comes to sand handling, pump selection is critical. Recent industry studies reveal that sand pumps can outperform traditional alternatives in various metrics. For instance, a report by the American Society of Civil Engineers indicates that sand pumps offer up to 30% more efficiency compared to conventional slurry pumps. This efficiency translates directly into cost savings over time.

Moreover, sand pumps exhibit longer operational lifespans. According to the Hydraulic Institute, these pumps can last up to 25% longer in abrasive conditions. This is crucial in mining, where wear and tear affect performance significantly. However, it's worth noting that not all projects may require the advanced capabilities of a sand pump. In some cases, simpler pumps might suffice, leading to reconsideration of costs versus benefits.

But, while the numbers seem promising, project managers must reflect on specific project needs. Some reports indicate a potential mismatch between pump capabilities and actual requirements. Choosing a pump based solely on performance statistics could lead to inefficiencies. Each project presents unique challenges, and a one-size-fits-all approach could backfire. Balancing technical specifications and real-world applications can be tricky.

Maintaining a sand pump is essential for its efficiency and longevity. Regular inspections are crucial. Check for loose bolts and connections. These can cause leaks or inefficiencies. Ensure that all seals are intact. Worn-out seals can lead to sand contamination, impacting performance.

Lubrication is another vital aspect. Use the appropriate type of lubricant for all moving parts.

Over-lubrication can attract sand particles, which may cause problems. The environment also plays a role in maintenance. If your pump operates in a dusty area, it requires more frequent cleaning. Dust can interfere with the motor and bearings.

Every pump will face wear and tear over time. Some parts might need replacement sooner than expected. Keeping a close eye on performance metrics can help identify issues early on. Sometimes, it’s easy to overlook small problems. However, these can escalate if not addressed. Regular maintenance checks can turn this around. This proactive approach often saves time and money in the long run.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.