Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

Choosing the right high pressure pump is crucial for optimizing industrial operations and achieving efficiency. According to a report by MarketsandMarkets, the global high pressure pumps market is projected to reach USD 3.96 billion by 2025, growing at a CAGR of 3.8% from 2020. This growth is driven by increasing demand in applications such as water treatment, oil and gas, and chemical processing. However, with a myriad of options available, selecting the appropriate pump can pose a challenge. Factors such as pressure ratings, flow rates, and compatibility with various fluids must be carefully considered to ensure the pump meets specific operational requirements. By understanding these parameters and the unique demands of your industry, you can make informed decisions that enhance productivity and reduce long-term operational costs.

When selecting a high pressure pump for industrial applications, several critical factors must be evaluated to ensure optimal performance and efficiency. First and foremost, consider the pump's capacity and pressure rating. It's essential to match the pump's specifications with the requirements of your specific application, whether it's for cleaning, material transfer, or testing. This will help in achieving the desired output without overexerting the pump, which can lead to premature wear or failure.

**Tips:** Always consult with manufacturers or suppliers to gather comprehensive data on pressure capabilities and flow rates. Comparing various models based on your workflow can also yield surprising insights that help in your decision-making process. Moreover, think about the pump's energy efficiency, as a more efficient model can lead to significant cost savings over time.

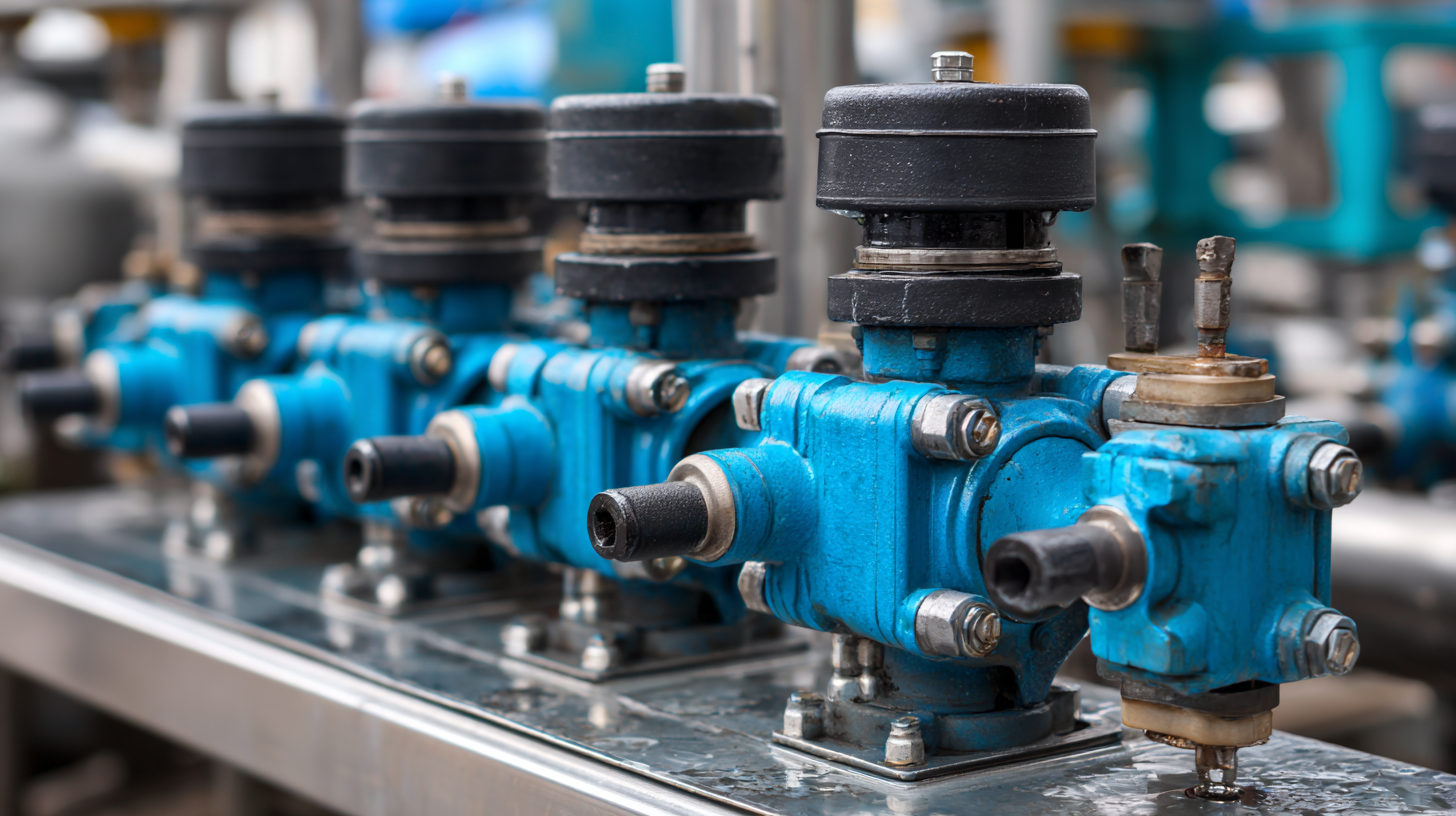

Another important aspect to consider is the type of fluid being pumped. Different fluids have varying viscosities and chemical compositions, which can affect pump selection. Make sure the materials used in the pump construction are compatible with the fluid to prevent corrosion or degradation.

**Tips:** Conduct a thorough fluid analysis to understand its characteristics and choose a pump specifically designed for those conditions. Also, consider potential maintenance requirements and the availability of replacement parts to ensure long-term operability.

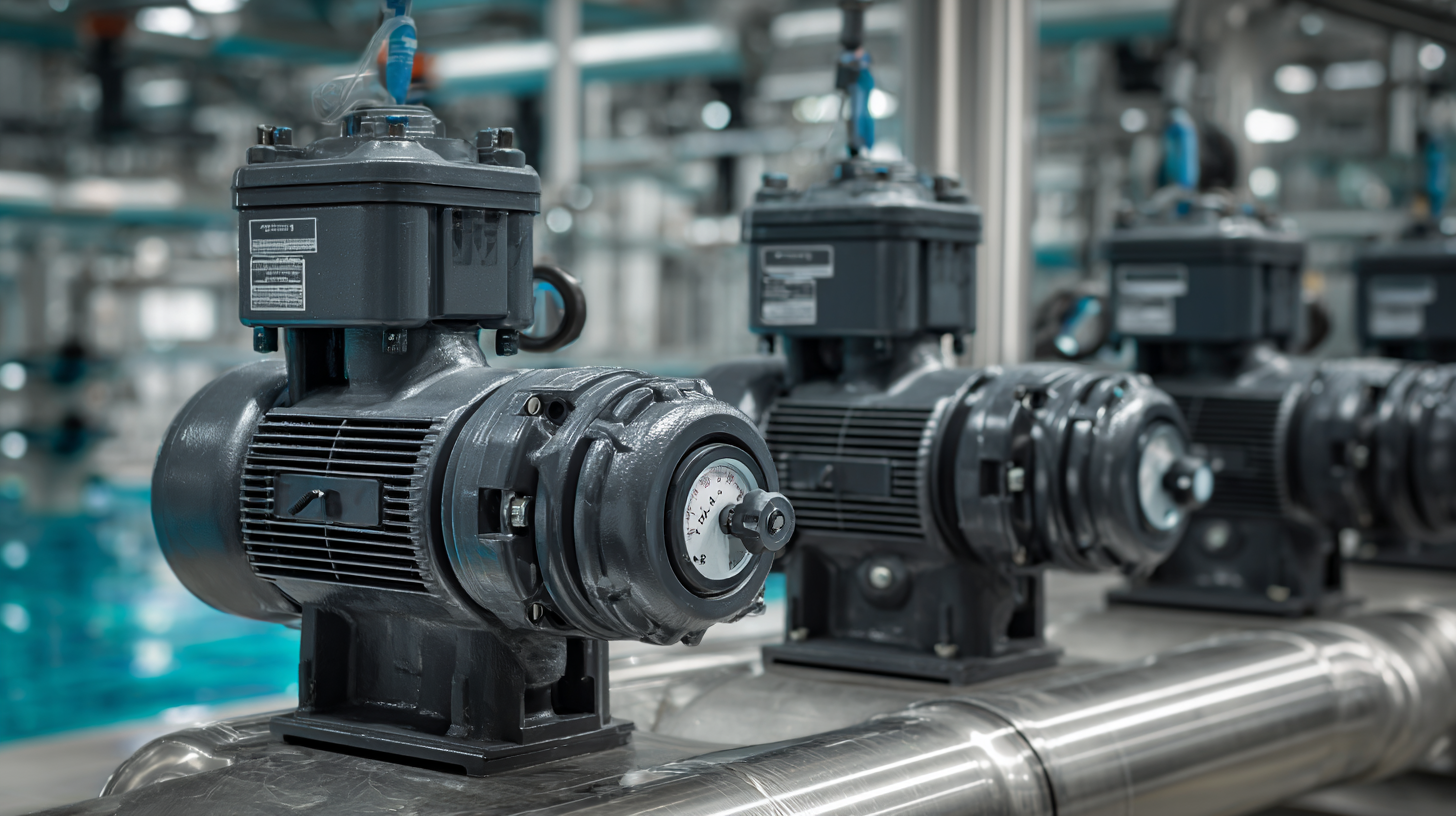

When selecting a high pressure pump for industrial applications, understanding the types of pumps available and their specific uses is crucial. High pressure pumps can be broadly categorized into positive displacement pumps and centrifugal pumps. Positive displacement pumps are ideal for applications that require precise flow control and high pressure, such as chemical processing and water jet cutting. They work by trapping a fixed amount of fluid and forcing it through the discharge, making them suitable for high viscosity fluids. On the other hand, centrifugal pumps are often employed in scenarios where large volumes of liquid need to be moved efficiently, such as in irrigation systems and cooling processes.

The choice between positive displacement and centrifugal pumps depends on various factors, including the type of fluid being pumped, the desired flow rate, and the operational pressure. For instance, cryogenic applications might use specialized positive displacement pumps to handle gases like nitrogen and oxygen at extremely low temperatures, while industries dealing with large fluid volumes may prefer centrifugal pumps for their ability to maintain flow rates efficiently. Understanding these distinctions helps businesses make informed decisions that optimize their operational efficiency and meet specific processing demands.

| Pump Type | Operating Pressure (psi) | Flow Rate (GPM) | Application |

|---|---|---|---|

| Diaphragm Pump | up to 5000 | 0.5 - 10 | Chemical transfer, wastewater treatment |

| Plunger Pump | up to 15000 | 1 - 50 | High-pressure cleaning, oil & gas |

| Gear Pump | up to 4000 | 0.5 - 20 | Hydraulic fluids, lubrication |

| Centrifugal Pump | up to 3000 | 10 - 500 | Cooling systems, water supply |

| Electric Submersible Pump | up to 6000 | 5 - 100 | Drilling, mining |

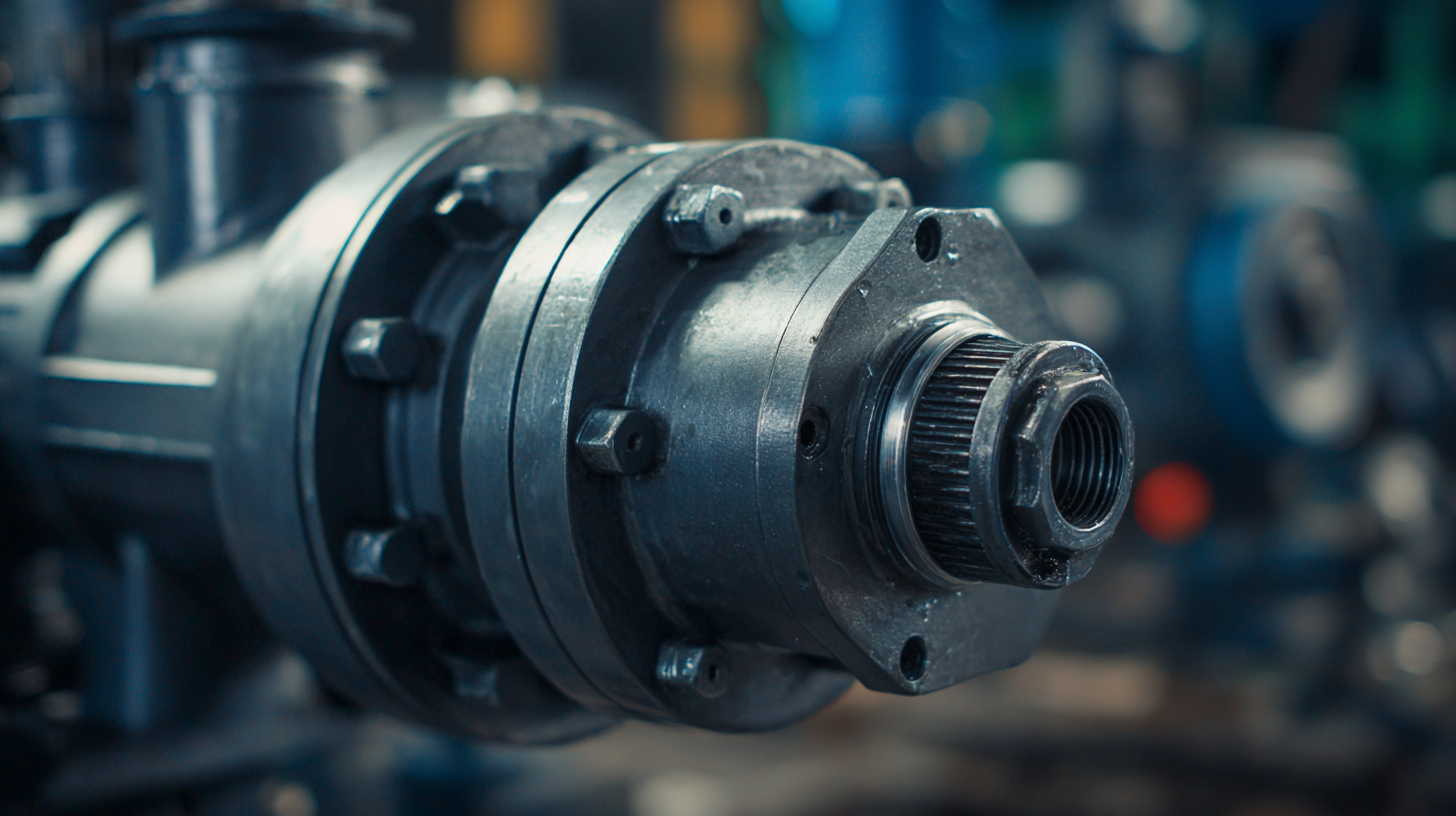

When selecting a high-pressure pump for industrial applications, evaluating the performance specifications is critical to ensuring that the pump meets operational requirements. Start by examining the flow rate, measured in liters per minute or gallons per minute, as it indicates the volume of fluid the pump can deliver. This is essential to determine if the pump can sustain the operational demands of your processes. Additionally, the pressure rating, expressed in psi or bar, helps identify whether the pump can achieve the necessary force to move fluids through your system efficiently.

Another important factor is the pump’s efficiency, which directly impacts energy consumption and operational costs. A higher efficiency means less energy is required to achieve the same output, making it a more cost-effective solution in the long run. Furthermore, consider the materials used in the pump construction, especially if it will handle corrosive or abrasive liquids. Choosing a pump made from durable materials ensures longevity and reduces maintenance costs. By carefully evaluating these performance specifications, you can make an informed decision that optimizes your industrial operations.

When selecting a high-pressure pump for industrial applications, understanding maintenance requirements is crucial for ensuring optimal performance and longevity. High-pressure pumps can face various operational stresses, making regular maintenance vital. Key maintenance tasks include routine inspections, which allow for the early detection of wear and tear, as well as the servicing of critical components like seals and bearings. By implementing a structured maintenance schedule, operators can minimize downtime and extend the lifespan of the pump.

Moreover, it's essential to familiarize yourself with the specific maintenance needs dictated by the pump type and manufacturer guidelines. For instance, diaphragm pumps may require different maintenance procedures compared to plunger pumps. Lubrication of moving parts is another aspect that shouldn’t be overlooked, as proper lubrication can significantly reduce friction and wear. Additionally, keeping the pump clean from debris and contaminants not only enhances performance but also prevents damage that could result from foreign particles entering the system. Regular monitoring of these factors can lead to smoother operation and cost savings in the long run.

When selecting a high-pressure pump for industrial applications, it's crucial to weigh cost against quality. Many businesses are tempted to opt for the cheapest option available, believing it will save money in the short term. However, lower-priced pumps often compromise on durability and performance, leading to increased maintenance costs and potential downtime. Investing in quality equipment may require a larger upfront expenditure, but it often results in better efficiency, longer lifespans, and ultimately, lower total cost of ownership.

Furthermore, the right pump should align with specific operational needs. A reliable, high-quality pump can enhance productivity and ensure consistent performance, which is particularly important in demanding industrial environments. By choosing quality over cost, businesses can benefit from advanced features, better warranties, and improved customer support, all of which contribute to a smoother operational flow. In the long run, making an informed decision rooted in quality rather than price alone can lead to significant savings and greater operational success.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.