Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

Choosing the right waste water pump is a crucial decision for both homeowners and businesses alike. A waste water pump system plays an integral role in managing and transporting non-potable water, ensuring that wastewater is efficiently moved to treatment facilities or disposal sites. Understanding the specific needs of your property, whether it’s a residential home or a commercial establishment, can significantly impact the effectiveness of your waste water management system.

When selecting a waste water pump, various factors need to be taken into consideration, including the type of waste being pumped, the volume of water to be managed, and the distance it needs to travel. Additionally, the characteristics of the installation site, such as elevation changes and drainage conditions, can further influence the choice of pump. With the right information, you can avoid common pitfalls and select a waste water pump that meets your needs efficiently and reliably.

In this guide, we will explore the key considerations and options available when choosing a waste water pump, helping you make informed decisions for optimal performance and longevity. Whether you are replacing an old system or installing a new one, understanding these essentials will lead you to the right solution for your waste water management challenges.

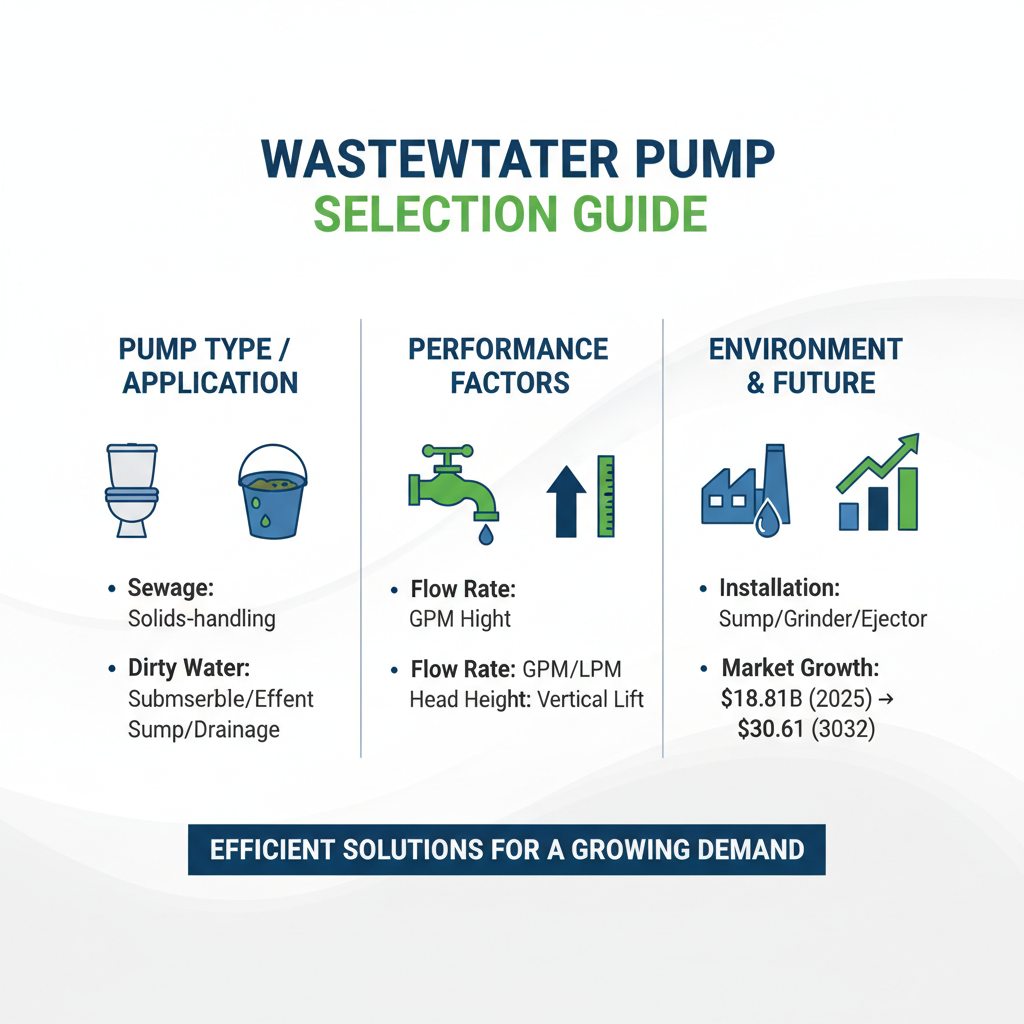

When selecting the right wastewater pump for your home or business, several critical factors deserve careful consideration. The specific application, such as sewage, dirty water, or stormwater, will influence the type of pump required. Key aspects such as flow rate, head height, and the environment where the pump will be used are essential to ensure optimal performance. For instance, the global water and wastewater pumps market is anticipated to expand significantly, growing from $18.81 billion in 2025 to a projected $30.61 billion by 2032, indicating rising demand for efficient pumping solutions.

Additionally, understanding the differences between pump types, such as submersible and non-submersible pumps, can help in making a more informed choice. A submersible pump, for example, is ideal for deep installations where space and accessibility are limited, while a non-submersible pump may be better for easier maintenance. Always consider energy efficiency ratings and the cost of operation over the pump's lifespan, as these factors can greatly impact the overall effectiveness and cost-saving potential of your wastewater management system.

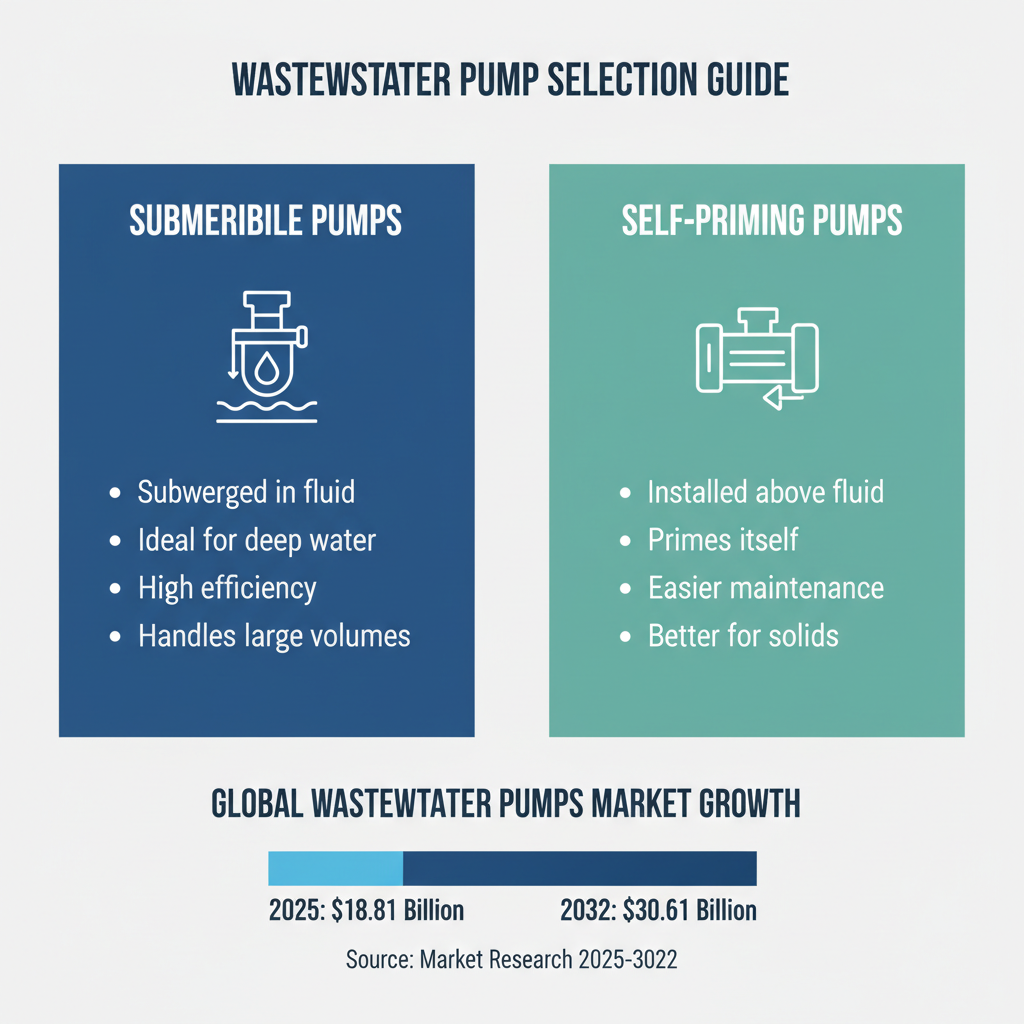

When selecting the appropriate wastewater pump for your home or business, understanding the two main types—submersible and self-priming pumps—is crucial.

Submersible pumps are designed to be submerged in the fluid they are pumping, making them ideal for deeper water applications. They are known for their efficiency and ability to handle larger volumes of wastewater.

Recent market research indicates that the global wastewater pumps market is projected to grow significantly, from $18.81 billion in 2025 to an astonishing $30.61 billion by 2032, highlighting the rising importance of effective wastewater management solutions.

In contrast, self-priming pumps are typically positioned above the water level, which allows them to draw liquid into the pump on their own. These pumps are easier to maintain and can be used in situations where submersible pumps are impractical.

According to industry analysts, the diversification of pump types driven by increased urbanization and environmental regulations has spurred notable growth in submersible mixer technologies, which are integral to sewage treatment processes.

As the efficiency of wastewater management systems becomes increasingly vital, understanding the distinctions between these pump types will aid in making informed decisions that align with specific operational needs.

When choosing the right wastewater pump, understanding the flow rate and head pressure requirements is essential. Flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates the volume of water the pump can move in a specific timeframe. On the other hand, head pressure refers to the height the pump must push the water, impacting its overall efficiency and performance. Evaluating both factors allows you to select a pump that meets your specific needs, whether for home or business use.

Tips for determining the right flow rate include assessing your daily water usage and the types of fixtures connected to the wastewater system. Additionally, consider the total vertical rise the pump will need to overcome, as this is crucial for calculating the required head pressure. It's often recommended to consult with a professional to ensure that all parameters are accurately considered, as this can significantly impact the lifespan and reliability of the pump.

Lastly, always factor in future needs. If you anticipate an increase in water usage or plan to add new appliances, it may be wise to select a pump with a higher capacity than currently required. This foresight can save you from having to replace the pump sooner than expected, ensuring seamless operation for years to come.

When selecting a wastewater pump for home or business use, several key features should be prioritized to ensure efficiency and reliability. First and foremost, consider the pump's capacity, which must match the expected flow rate of wastewater. Pumps are designed to handle specific volumes of water, and selecting one that can accommodate peak demands is crucial to prevent overflow and operational interruptions.

Another significant aspect is the pump's energy efficiency. A pump that operates with lower energy consumption can significantly reduce operational costs in the long run. Additionally, look for features like automatic controls, which facilitate easy operation and monitoring, as well as durable materials that can withstand corrosive wastewater environments. Reliability is also paramount; pumps must deliver consistent performance, especially during emergencies like flooding, when time is of the essence. By focusing on these features, homeowners and businesses can ensure effective wastewater management that meets their specific needs.

| Feature | Importance | Recommended Specification |

|---|---|---|

| Power Source | Ensures reliable operation regardless of power shortages | Electric / Gasoline |

| Flow Rate | Determines the speed at which water can be moved | 20-100 GPM |

| Lift Height | Indicates how high the pump can push water | Up to 25 feet |

| Material | Affects durability and corrosion resistance | Stainless Steel / Thermoplastic |

| Impeller Type | Critical for handling solids and debris | Vortex / Semi-Vortex |

| Noise Level | Affects comfort in residential areas | Low (< 60 dB) |

| Automatic Float Switch | Ensures automatic operation without manual intervention | Yes |

Maintenance is critical for ensuring the optimal performance of wastewater pumps in both residential and commercial settings. According to a report by the Water Environment Federation, proper maintenance can extend the lifespan of wastewater pumps by up to 40%. Regular inspections, including checking for leaks, pump vibrations, and unusual noises, can help mitigate potential issues before they escalate. It’s recommended to perform these checks at least once a month to ensure the pump operates efficiently.

In addition to regular inspections, routine cleaning is essential. Clogged filters and impellers can impair pump performance significantly, leading to decreased efficiency and potential failures. The Hydraulic Institute suggests that operators should thoroughly clean their pumps and associated components every six months, especially in environments with high sediment or debris levels. Additionally, lubricating moving parts according to the manufacturer's guidelines can significantly reduce friction and wear, ensuring smoother operation and prolonging the lifespan of the pump. By prioritizing maintenance, users can ensure their wastewater pumps remain effective and reliable for years to come.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.