Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

Choosing the right high pressure pumps for your specific applications can significantly influence the efficiency and effectiveness of your operations. High pressure pumps are essential in various industries, from agriculture to manufacturing, and selecting the best one requires careful consideration of several factors. This guide will provide you with the top 10 tips to navigate the complexities of high pressure pump selection, ensuring you make an informed decision that meets your needs.

In the diverse world of high pressure pumps, understanding their functionality, specifications, and the specific requirements of your projects is critical. With a plethora of options available, it can be overwhelming to determine which pump will deliver the optimal performance for your applications. The following tips will help demystify this process, equipping you with the knowledge to choose a high pressure pump that not only fits your technical requirements but also aligns with your budget and operational goals. Whether you are a seasoned professional or new to the field, this guide aims to simplify your decision-making and enhance your understanding of high pressure pump technology.

High-pressure pumps are specialized devices designed to generate fluid flow at high pressures, typically exceeding 200 psi. These pumps are essential in various applications, including industrial cleaning, agriculture, and construction. By creating a powerful stream of water or other fluids, high-pressure pumps efficiently clean surfaces, apply chemicals, or assist in the injection of water into subsurface wells. Their robust design makes them ideal for handling demanding tasks that require reliability and consistent performance.

Understanding the specific applications of high-pressure pumps is crucial for selecting the right model for your needs. For instance, in industrial settings, pumps are often used for wastewater management, while in agriculture, they may be utilized for irrigation and pesticide application. The choice of a high-pressure pump should also consider factors such as flow rate, power source, and maintenance requirements. By assessing the operational environment and intended use, users can ensure they select a pump that meets their performance expectations and provides long-term value.

When choosing a high pressure pump, understanding the key specifications such as pressure ratings and flow rates is crucial. Pressure ratings indicate the maximum pressure that the pump can handle, which directly affects its suitability for various applications. For instance, a pump with a higher pressure rating is ideal for tasks that require delivering water to great heights or overcoming significant resistance in pipelines. It's important to assess the specific needs of your project to select a pump that meets the required pressure capacity while ensuring reliability and efficiency under operating conditions.

Flow rates, measured in gallons per minute (GPM) or liters per minute (LPM), are another vital specification to consider. The flow rate determines how quickly a pump can deliver fluid, directly impacting the speed of your operations. Depending on the application—whether it's cleaning, irrigation, or industrial processes—you may need a pump with a higher flow rate to maintain productivity. Evaluating the balance between pressure ratings and flow rates will ensure optimal performance, as an overemphasis on one can lead to inefficiencies or even pump failure. Understanding these specifications helps you make an informed decision and ensures that the chosen pump aligns with your specific operational needs.

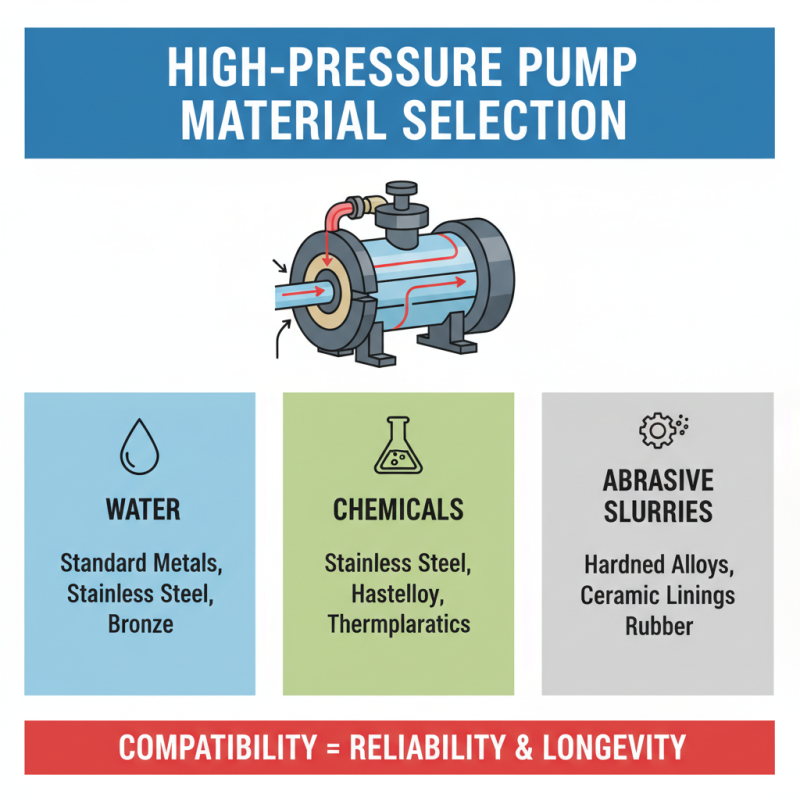

When selecting high pressure pumps, the compatibility of materials with the fluids they will handle is crucial. Different mediums, such as water, chemicals, or abrasive slurries, can significantly affect the performance and lifespan of the pump. Choosing a pump made from materials that can withstand corrosion, erosion, or chemical reactions is essential to ensure reliable operation and reduce the risk of failure. Stainless steel, for example, is often chosen for its strength and resistance to various chemicals, while thermoplastics might be suitable for less aggressive environments.

Additionally, considering temperature and pressure ratings of the materials is vital. Certain mediums may require pumps that can handle high temperatures or provide exceptional sealing capabilities to prevent leaks. It is important to review the material specifications carefully and consult with manufacturers if necessary to ensure that the selected pump will function optimally under the specific conditions it will face. By prioritizing material compatibility, users can prolong the operational life of their pumping systems and minimize maintenance costs, leading to overall improved efficiency in their applications.

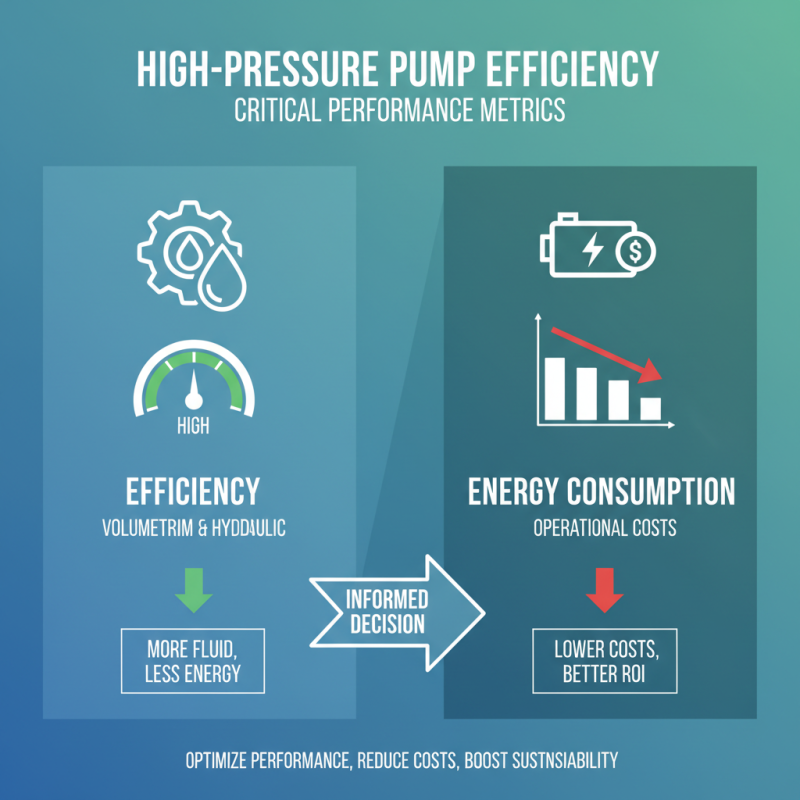

When selecting a high-pressure pump, efficiency and energy consumption are critical performance metrics that can significantly impact operational costs and sustainability. A pump that operates efficiently can move more fluid while consuming less energy, which is particularly important in industrial applications where long hours of operation are common. Therefore, understanding the pump's efficiency rating, specifically its volumetric and hydraulic efficiency, can guide users in making informed decisions. Additionally, calculating the pump's energy consumption can help in assessing its long-term operational costs, allowing for a better return on investment.

To evaluate the performance metrics of high-pressure pumps, it’s essential to consider the pump's duty cycle, flow rate, and head pressure. A pump that meets the required specifications without over-exerting itself will inherently be more energy-efficient. For instance, a pump designed for specific flow rates and pressure requirements will likely operate more efficiently than a one-size-fits-all model. Moreover, features like variable frequency drives (VFDs) can enhance energy savings by adjusting the pump's speed to meet changing demands, which minimizes unnecessary energy use. Analyzing these metrics thoroughly ensures that the pump not only meets the operational needs but also aligns with energy conservation goals.

When selecting high pressure pumps, one of the most crucial aspects is choosing the right manufacturer. A reliable manufacturer should possess strong industry credentials, which can often be assessed through certifications, compliance with industry standards, and a proven track record of successful projects. It's essential to look for certifications that indicate adherence to quality management systems and safety protocols, as these demonstrate a commitment to producing equipment that meets or exceeds operational expectations.

In addition to industry credentials, the level of support and service provided by a manufacturer can significantly affect the overall experience. Look for companies that offer comprehensive customer support, including technical assistance, availability of spare parts, and warranty services. Manufacturers that invest in customer education and provide detailed product documentation, manuals, and training resources signal their dedication to building long-term relationships. This support ensures that you can effectively operate and maintain your high pressure pump, leading to improved performance and longevity.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.