Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the evolving landscape of industrial fluid management, the selection of an appropriate

diaphragm transfer pump has become paramount for operational efficiency and process reliability. According to the

Global Market Insights

report, the diaphragm pump market is projected to surpass $5 billion by 2025, driven

by increasing demand across diverse sectors such as chemical processing, food and beverage, and pharmaceuticals.

This rapid growth underscores the necessity for stakeholders to understand the distinct features and applications of

diaphragm transfer pumps to optimize their operations.

Industry expert Dr. Sarah Thompson, a leading authority in fluid dynamics, emphasizes the

importance of tailored solutions in her research, stating, “Choosing the right diaphragm transfer pump is not just

about specifications; it’s about aligning the pump's capabilities with the unique needs of your application.” Such insights

highlight the critical factors to consider—flow rate, material compatibility, and operational environment—when

selecting a diaphragm transfer pump. As businesses continue to seek enhanced performance and sustainability, understanding

these elements will empower decision-makers to make informed choices that elevate their operational standards and reduce downtime.

Industry expert Dr. Sarah Thompson, a leading authority in fluid dynamics, emphasizes the

importance of tailored solutions in her research, stating, “Choosing the right diaphragm transfer pump is not just

about specifications; it’s about aligning the pump's capabilities with the unique needs of your application.” Such insights

highlight the critical factors to consider—flow rate, material compatibility, and operational environment—when

selecting a diaphragm transfer pump. As businesses continue to seek enhanced performance and sustainability, understanding

these elements will empower decision-makers to make informed choices that elevate their operational standards and reduce downtime.

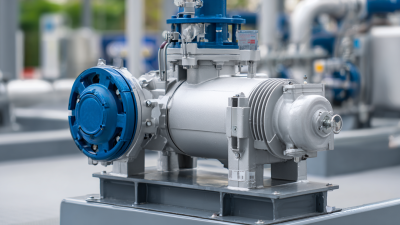

Diaphragm transfer pumps play a crucial role in a variety of industrial applications, providing an efficient solution for moving fluids. Understanding the basics of these pumps is essential for selecting the right one for your specific needs. A diaphragm pump typically consists of a flexible membrane that separates the fluid chamber from the pump's drive system. This design ensures that the fluid remains isolated, which is particularly advantageous when handling aggressive or hazardous substances. According to a report by MarketsandMarkets, the diaphragm pump market is projected to grow at a CAGR of 7.1% from 2021 to 2026, highlighting the increasing reliance on this technology across sectors.

When choosing a diaphragm pump, key considerations include flow rate, pressure requirements, and the type of fluid being transferred. For example, pumps designed for low-flow applications, typically below 10 GPM (gallons per minute), might suit processes in laboratories or small-scale manufacturing. In contrast, larger operations may demand pumps capable of handling flows exceeding 250 GPM. Additionally, material selection is paramount; a pump made from thermoplastic materials may be suitable for corrosive chemicals, while those using stainless steel are ideal for food-grade applications. Understanding these fundamentals aids users in making informed decisions that enhance efficiency and safety in their operations.

| Feature | Description | Recommended Use | Flow Rate (GPM) | Maximum Pressure (PSI) |

|---|---|---|---|---|

| Material Compatibility | Ensure pump materials are compatible with the liquid being transferred. | Chemical transfer, agricultural applications | 1-10 | 30-100 |

| Pump Size | Consider the size and space available for installation. | Limited installation space, portable applications | 0.5-5 | 20-50 |

| Power Source | Choose between electric, pneumatic, or manual operation. | Remote locations, energy efficiency | 2-20 | 15-60 |

| Seal Type | Select seals based on the fluid being pumped and service conditions. | Hazardous materials, high viscosity fluids | 1-15 | 25-80 |

| Maintenance Requirements | Assess how often and what type of maintenance will be needed. | Frequent usage, high operational demands | 1-10 | 30-90 |

When selecting the right diaphragm transfer pump for your needs, several key factors should be considered to ensure optimal performance and efficiency. First, consider the fluid type you will be transferring. Diaphragm pumps are ideal for handling various substances, including corrosive chemicals and slurries, making them suitable for industries such as chemical processing and wastewater treatment. Make sure the materials used in the pump are compatible with the fluids to prevent degradation and ensure safe operation.

Another important factor is the pump's operating pressure and flow rate capabilities. Different applications may require specific pressure thresholds and flow rates to achieve desired results. It's essential to assess the system requirements and determine if the diaphragm pump can meet those criteria. Additionally, recent advancements in diaphragm pump technology, such as electric operation, have improved energy efficiency and reliability, making these options increasingly attractive for industrial applications. When evaluating diaphragm pumps, focus on the operation mode that aligns with your energy efficiency goals while maintaining effective fluid transfer.

When selecting the right diaphragm transfer pump, understanding flow rate and pressure requirements is critical for optimal performance in your application. The global diaphragm pump market is projected to grow from $6.35 billion in 2025 to $9.06 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.21%. This growth can be attributed to increasing demand across various industries, necessitating pumps that can maintain accuracy and reliability under diverse operational conditions.

Evaluating the specific flow rate and pressure needs of your system will determine the type of diaphragm transfer pump suitable for your application. For instance, applications involving high-viscosity fluids or solids may require pumps that can handle thicker materials without compromising performance. Furthermore, modern pumps integrated with advanced technologies can enhance efficiency, particularly as industries face pressure from evolving standards and enhanced productivity demands. As such, companies must assess their unique requirements carefully to choose pumps that provide the best fit for their operational goals.

This chart illustrates the flow rate (in liters per minute) and pressure (in psi) requirements for various applications utilizing diaphragm transfer pumps. Understanding these parameters is essential for selecting the right pump for your needs.

When selecting a diaphragm transfer pump, material compatibility is a crucial factor that directly influences performance and longevity. The primary materials used in diaphragm pumps include rubber, thermoplastics, and metals, each offering distinct advantages depending on the fluid being transferred.

For example, if the pump is intended for corrosive chemicals, selecting a diaphragm made of materials like PTFE or EPDM can prevent degradation and ensure safe operation. It’s essential to consider the chemical composition of the fluids, as some materials can react adversely, affecting both pump efficiency and safety.

Additionally, the environment in which the pump will operate should inform your material choices. Factors such as temperature fluctuations, exposure to UV rays, and potential abrasiveness of the fluids can impact the longevity and reliability of the pump components. For abrasive slurries, opting for a diaphragm made from reinforced materials can enhance durability. Conducting thorough research and consulting with manufacturers will ultimately aid in selecting the most suitable materials, ensuring that the diaphragm pump meets specific operational requirements effectively.

When selecting a diaphragm transfer pump, one of the most critical factors is ensuring its longevity through proper maintenance and support. Regular maintenance is key to preventing potential issues and extending the lifespan of your pump. This includes routine inspections, checking for leaks, and ensuring that all components, such as diaphragms and valves, are functioning correctly. By establishing a maintenance schedule, users can identify wear and tear early, facilitating timely replacements and minimizing downtime.

Moreover, seeking out manufacturers that offer reliable support is equally important. A good support system provides access to technical assistance, troubleshooting resources, and replacement parts when needed. In addition, consider the availability of guidance on optimal operating conditions to avoid excessive strain on the pump. Manufacturers that prioritize customer service often have extensive documentation, including user manuals and maintenance guides, which can be invaluable for keeping the pump running efficiently. By focusing on maintenance and support, users can achieve maximum performance and reliability from their diaphragm transfer pumps.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.