Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

When it comes to maintaining optimal water quality in various applications, selecting the right pressure filter is crucial. As John Smith, a leading expert in water filtration technology, aptly states, "Understanding the complexities of pressure filters can transform your water treatment process into a seamless, efficient operation." With many options available on the market, knowing how to choose the right pressure filter and maintain it effectively can significantly impact performance and longevity.

The process of selecting a pressure filter involves various considerations, including the specific needs of your system, the type of contaminants present, and the expected flow rates. Moreover, caregivers of these systems must be diligent in their maintenance practices. Regular checks and timely servicing can prevent common issues, ensuring that the pressure filter works at peak efficiency. This article explores ten essential tips for both choosing and maintaining your pressure filter, empowering users to make informed decisions for their filtration needs. Whether you're in an industrial setting or managing a municipal water supply, the insights provided herein will lead to enhanced filtration performance and overall satisfaction.

Pressure filters play a critical role in modern water systems, ensuring the delivery of clean and safe water for various applications. According to a report from the Water Quality Association, approximately 35% of households in the United States use some form of water filtration system, highlighting the growing reliance on effective filtration technologies. These systems work by applying pressure to drive water through filter media, effectively removing particulates, sediments, and even harmful pathogens. In industrial applications, pressure filters are essential for maintaining process efficiency and product quality, especially in sectors like food and beverage, pharmaceuticals, and chemical manufacturing.

The importance of maintaining pressure filters cannot be overstated. Regular maintenance not only extends the lifespan of the filters but also ensures optimal performance. The American Water Works Association suggests that improper maintenance can lead to a 30% reduction in filtering efficiency, which can result in subpar water quality and increased operational costs. By implementing a comprehensive maintenance schedule, users can avoid common pitfalls such as clogging, pressure drops, and reduced flow rates, and ensure their systems continue to operate effectively, safeguarding health and compliance within water treatment regulations.

| Tip Number | Tip Description | Importance | Maintenance Frequency |

|---|---|---|---|

| 1 | Choose the right filter size based on your system's needs. | Ensures optimal flow and efficiency. | Annually |

| 2 | Assess the water quality and contaminant types. | Helps in selecting appropriate media. | Semi-annually |

| 3 | Regularly check and replace filter media. | Maintains filter effectiveness. | Every 6 months |

| 4 | Monitor pressure drop across the filter. | Indicates when maintenance is needed. | Monthly |

| 5 | Ensure proper installation and sealing of the filter. | Prevents leaks and inefficiencies. | During installation |

| 6 | Use appropriate backwashing techniques if applicable. | Removes accumulated debris and extends filter life. | As needed |

| 7 | Regularly inspect the filter housing for damage. | Prevents system failures. | Quarterly |

| 8 | Maintain proper flow rates as per manufacturer's guidelines. | Optimizes overall system performance. | Constantly |

| 9 | Keep records of maintenance and filter performance. | Aids in troubleshooting and future planning. | Every maintenance session |

| 10 | Consult with professionals for complex systems. | Ensures optimal setup and maintenance. | As necessary |

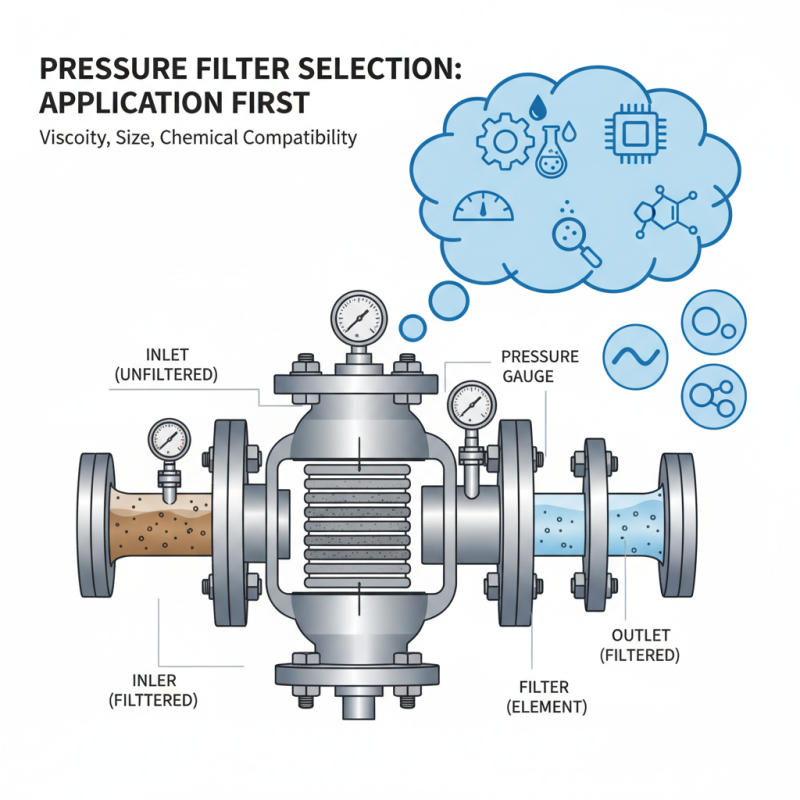

When selecting a pressure filter, the first factor to consider is the application for which you need the filter. Different industries and uses may require specific types of filters, designed for various pressure ranges, flow rates, and filtration degrees. Assess the nature of the materials you will be filtering, including their viscosity, size, and chemical compatibility with the filter media. Understanding these requirements will help ensure you choose a filter that meets your operational demands effectively.

Additionally, the size and capacity of the pressure filter are crucial. Determine the volume of liquid that needs to be filtered and how fast you need the process to occur. This will guide you in selecting a filter that can handle your required flow rates without compromising performance. Maintenance considerations should also influence your decision; look for filters that are easy to clean and service. Regular maintenance routines can significantly extend the life of the filter and enhance its efficiency, making it a vital aspect of the selection process.

Proper installation and setup of your pressure filter are crucial for optimal performance and longevity. Begin by selecting an appropriate location that is easily accessible for maintenance yet away from direct sunlight or extreme temperatures. The foundation should be stable and level to prevent any undue stress on the filter. Before installation, ensure that the unit is clean and free from debris, as this can impact its efficiency. Carefully read through the manufacturer’s manual to familiarize yourself with the specific requirements for your model, including necessary connections and fittings.

Once you have prepared the site, it’s essential to connect the pressure filter to your water source and any additional components, such as pumps or controllers. Use high-quality hoses and fittings to prevent leaks, and ensure all connections are tight. After setup, check the filter for any possible leaks before filling it with water. Once the system is filled, run the filter through a test cycle while monitoring its performance. This initial run will help identify any issues that may need addressing before full operation. Regularly check the pressure gauge and ensure that the filter media is clean, as this will contribute to a longer lifespan and efficient filtration.

Regular maintenance is crucial for extending the lifespan of your pressure filter. One of the most important practices is to establish a routine cleaning schedule. Not only does this prevent clogging and ensure optimal performance, but it also helps in identifying any wear and tear early on. Cleaning the filter media according to the manufacturer's guidelines, while keeping an eye out for any unusual pressure drops, can save both time and money in the long run.

Another vital aspect of maintenance is monitoring the pressure levels consistently. Regular checks allow you to detect any inconsistencies that may indicate underlying issues. It’s also beneficial to replace any worn-out seals or O-rings promptly, as these parts are essential for maintaining proper pressure and preventing leaks.

Additionally, keeping a detailed maintenance log can help track performance changes over time and inform future servicing decisions. Implementing these regular maintenance practices will not only enhance the efficiency of your pressure filter but also significantly prolong its service life.

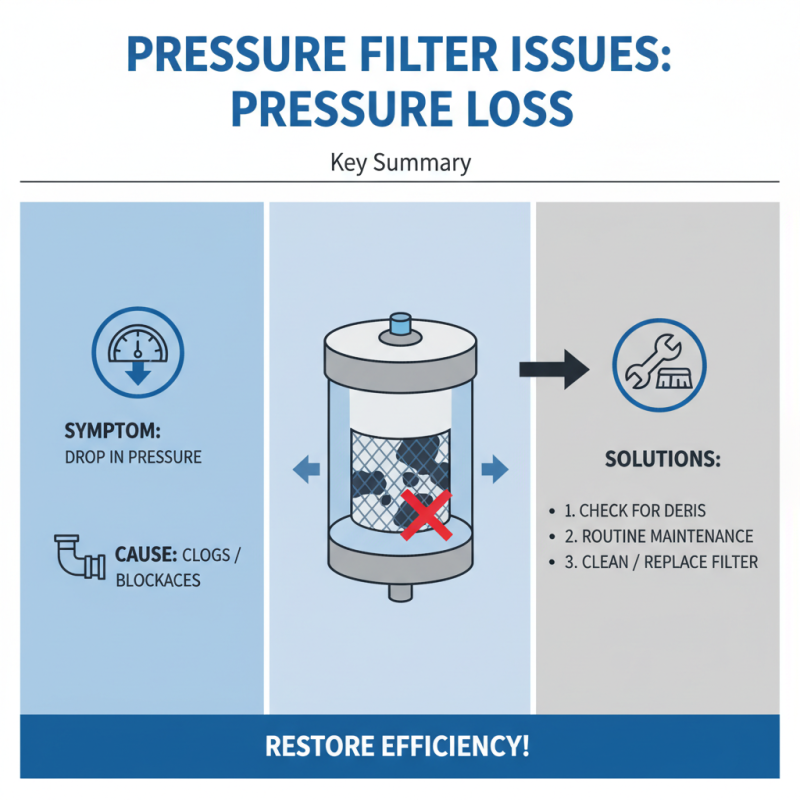

When working with pressure filters, it’s essential to be prepared for potential issues that can arise during operation. One common problem is pressure loss, which often occurs due to clogs or blockages in the filter media. Regularly checking for debris and performing routine maintenance can significantly reduce the likelihood of this issue. If you notice a drop in pressure, inspect the filter for any visible obstructions, and clean or replace the filter elements as needed to restore efficiency.

Another issue frequently encountered is leaks, which can compromise system performance and safety. Leaks might originate from faulty seals or connections. Regularly inspect all fittings and gaskets to ensure proper sealing. If a leak is detected, it’s crucial to identify its source promptly and take corrective measures, such as tightening connections or replacing faulty components. Additionally, monitoring the pressure gauge can provide early warnings of abnormal conditions, giving you the chance to address issues before they escalate.

Lastly, inconsistent flow rates can indicate underlying problems within the filter system. This could stem from improper sizing of the filter for your application or a need for cleaning due to accumulated contaminants. Conducting periodic evaluations of flow rates and comparing them to baseline measurements will help identify deviations. If inconsistencies persist, reevaluating the system design or consulting with a filtration expert may be necessary to ensure optimal operation and longevity of your pressure filter.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.