Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In today's world, the importance of clean and purified water cannot be overstated, particularly in various industries ranging from agriculture to aquaculture. One key component that plays a vital role in achieving this goal is the filtration pump. A filtration pump is designed to remove impurities and particles from water, ensuring that the final output is safe and suitable for its intended use. Understanding the different types and functions of filtration pumps can help users select the best option for their specific needs.

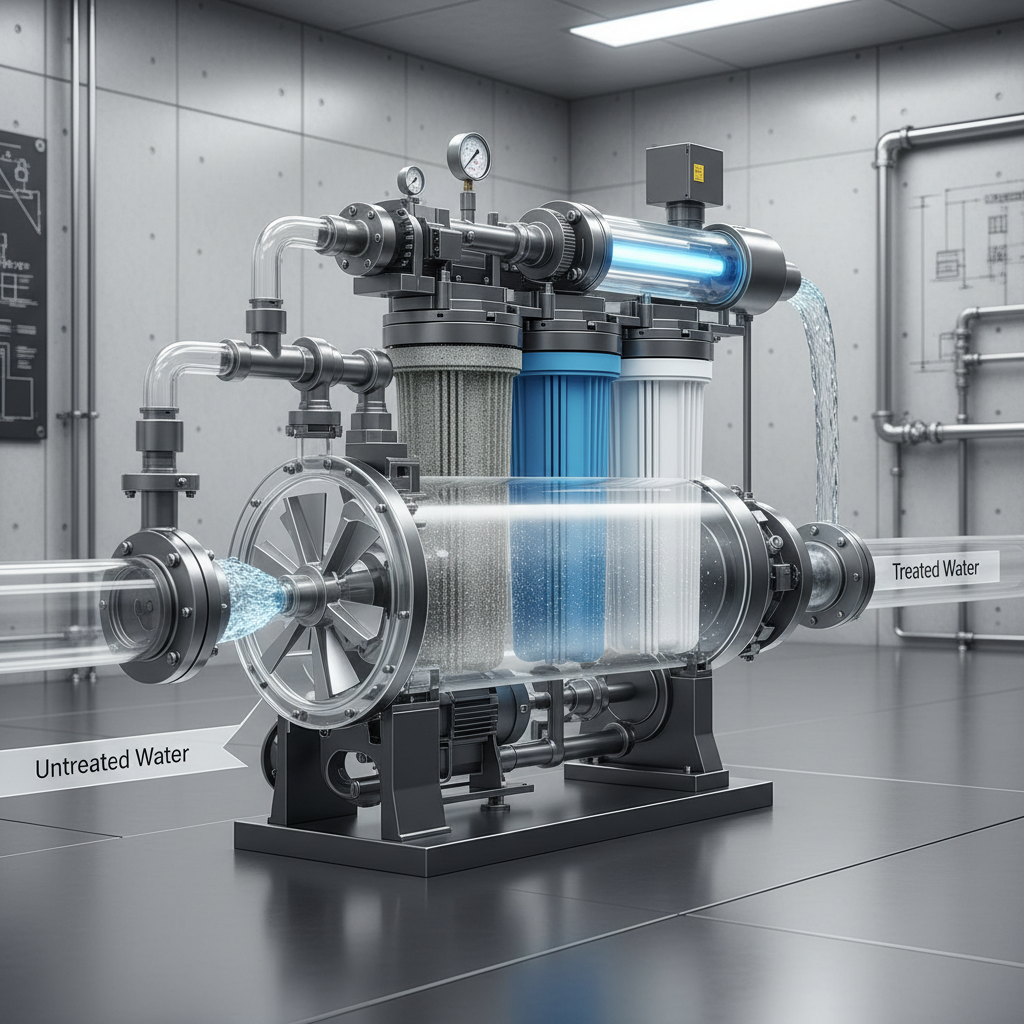

Filtration pumps are essential devices used across various industries to ensure the purity and quality of liquids. They work by removing impurities and particles from fluids, thus maintaining optimal conditions for processes such as water treatment, aquaculture, and swimming pool maintenance. The effectiveness of a filtration pump is determined by its ability to filter out contaminants and deliver clean liquid, making it a critical component in systems that require continuous fluid circulation.

Different types of filtration pumps serve diverse applications, from submersible models suited for wastewater management to more sophisticated multi-stage pumps used in industrial settings. Each type is designed to handle specific flow rates and levels of contamination, reflecting the unique requirements of the environment they are employed in. Understanding these differences is crucial for selecting the appropriate filtration pump for a given task, ensuring efficient operation and longevity of the equipment involved. This versatility and adaptability highlight the significant role filtration pumps play in safeguarding both public health and industrial processes.

| Type | Function | Common Applications | Flow Rate (GPH) |

|---|---|---|---|

| Submersible Pump | Removes water and debris from below the surface | Swimming Pools, Basements | 500 - 4000 |

| Centrifugal Pump | Moves water using rotational energy | Industrial Filtration, Water Treatment | 100 - 5000 |

| Vacuum Pump | Creates a vacuum to remove particles from liquids | Laboratories, Chemical Processing | 10 - 300 |

| Diaphragm Pump | Uses a diaphragm to pump fluid and provides precise control | Food Processing, Pharmaceutical | 30 - 400 |

| Recirculation Pump | Maintains circulation of water and chemicals | Aquariums, Spa Systems | 100 - 3000 |

Filtration pumps are essential in various industries, serving to remove impurities from liquids. These pumps come in several types, each designed for specific applications. The most common types include submersible pumps, centrifugal pumps, and diaphragm pumps. Submersible pumps are submerged in the liquid they pump, making them ideal for applications such as drainage and wastewater management. They efficiently move water from flooded areas, providing a quick solution to excess liquid.

Centrifugal pumps, on the other hand, are widely used in industrial and agricultural settings. They operate by converting rotational energy into hydrodynamic energy, making them suitable for pumping large volumes of liquid quickly. These pumps are often found in irrigation systems or as part of larger processing operations. Diaphragm pumps, known for their versatility, are commonly used in chemical transfer and water treatment processes. Their design allows for the safe handling of corrosive materials, making them an ideal choice in environments that require strict contamination control. Each type of filtration pump plays a crucial role in maintaining system efficiency and ensuring the integrity of the liquids being processed.

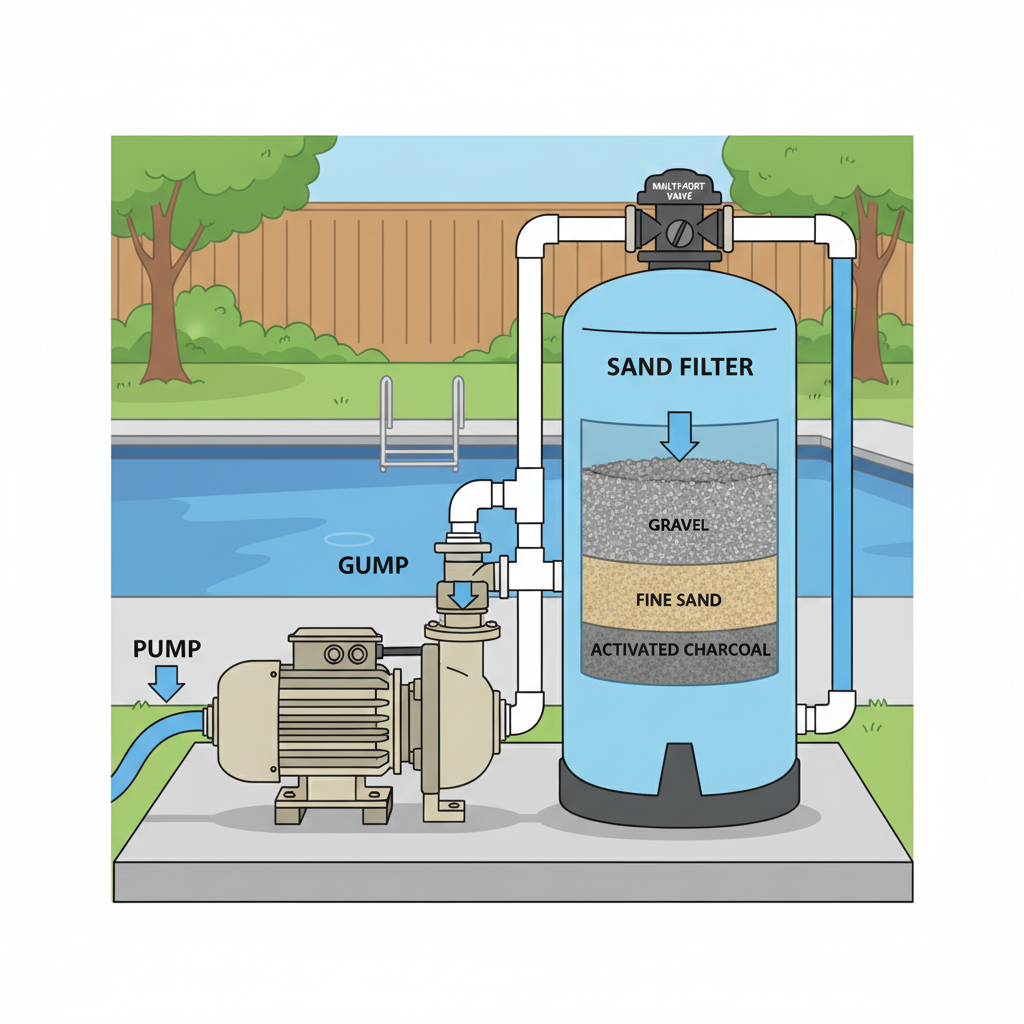

Filtration pumps play a crucial role in various applications, particularly in maintaining water clarity and cleanliness in pools, aquariums, and industrial processes. Understanding their key components is essential for grasping how these systems operate efficiently. At the heart of a filtration pump is the motor, which drives the impeller. This impeller creates the necessary suction to draw water into the filtration system, where debris and contaminants are removed.

Another integral part of filtration pumps is the filter media, which can vary in type from sand and cartridges to diatomaceous earth. As water flows through the filter media, it captures particles as small as a few microns, ensuring a thorough cleaning process. Additionally, many filtration pumps are equipped with pressure gauges that monitor the system's performance, indicating when maintenance is needed. Understanding these components and their functions enables users to maintain and operate filtration systems efficiently, ensuring optimal performance.

Filtration pumps play a crucial role in various applications, from aquariums to industrial processes, ensuring that water or other fluids remain clean and clear. To maximize their efficiency and longevity, regular maintenance is essential. Here are some tips to keep your filtration pump running optimally.

First and foremost, check and clean the filters regularly. Clogged filters can impede water flow and strain the pump, leading to potential damage. Depending on the pump's usage, this maintenance task should be performed weekly or monthly. Additionally, inspect the pump for any signs of wear or leaks, as promptly addressing these issues can prevent larger, more costly repairs down the line.

Another key tip is to ensure that the pump is correctly sized for its application. An undersized pump may struggle to handle the volume of fluid, while an oversized one could lead to unnecessary energy consumption. Properly aligning and securing the pump can also reduce vibrations and noise, contributing to a more efficient operation. By following these maintenance tips, you can enhance the performance and lifespan of your filtration pump.

Filtration pumps play a crucial role across various industries, facilitating effective water management and treatment processes. These pumps ensure the removal of impurities from water, delivering clean and safe water essential for both industrial and residential applications. Industries such as agriculture, wastewater treatment, and manufacturing heavily rely on filtration pumps to maintain operational efficiency and compliance with regulatory standards.

According to market research, the global water pumps market is projected to reach USD 93.10 billion by 2033, with a compound annual growth rate (CAGR) of 4.54% from 2025 to 2033. This growth highlights the increasing demand for effective filtration solutions in water management. Moreover, the ongoing trends in the water management industry, such as the rise of smart water solutions and sustainable practices, further emphasize the importance of filtration pumps in enhancing water quality and promoting environmental sustainability. As industries adapt to these trends, the role of filtration pumps continues to expand, driving innovation and growth within the sector.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.