Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

High pressure slurry pumps are transforming industrial processes by significantly enhancing efficiency and productivity across various sectors. According to a recent report by Allied Market Research, the global slurry pump market is projected to reach $5.21 billion by 2026, growing at a CAGR of 4.5%. This growth underscores the increasing importance of high pressure slurry pumps in handling abrasive and viscous materials in industries such as mining, construction, and wastewater treatment. By utilizing advanced technology and materials, these pumps are designed to operate under extreme pressure conditions, allowing for improved flow rates and reduced energy consumption. As manufacturers strive for greater operational efficiency, adopting high pressure slurry pumps not only streamlines processes but also helps reduce maintenance costs, making them an indispensable tool in modern industrial applications.

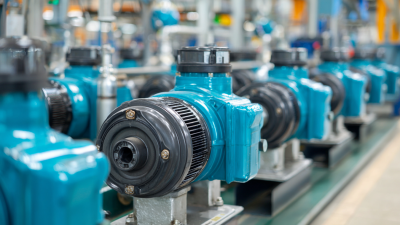

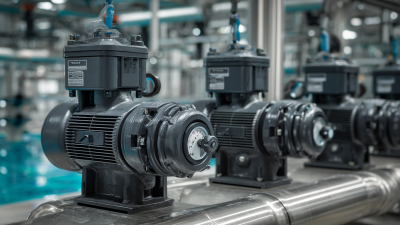

High pressure slurry pumps play a crucial role in various industrial processes, particularly in sectors such as mining, mineral processing, and wastewater management. These pumps are designed to transport abrasive and viscous slurries—mixtures of liquids and solid particles—effectively, even under challenging conditions. Their robust construction and powerful performance enable them to handle high flow rates and pressures, ensuring that materials can be moved efficiently through processing systems without risk of damage or downtime.

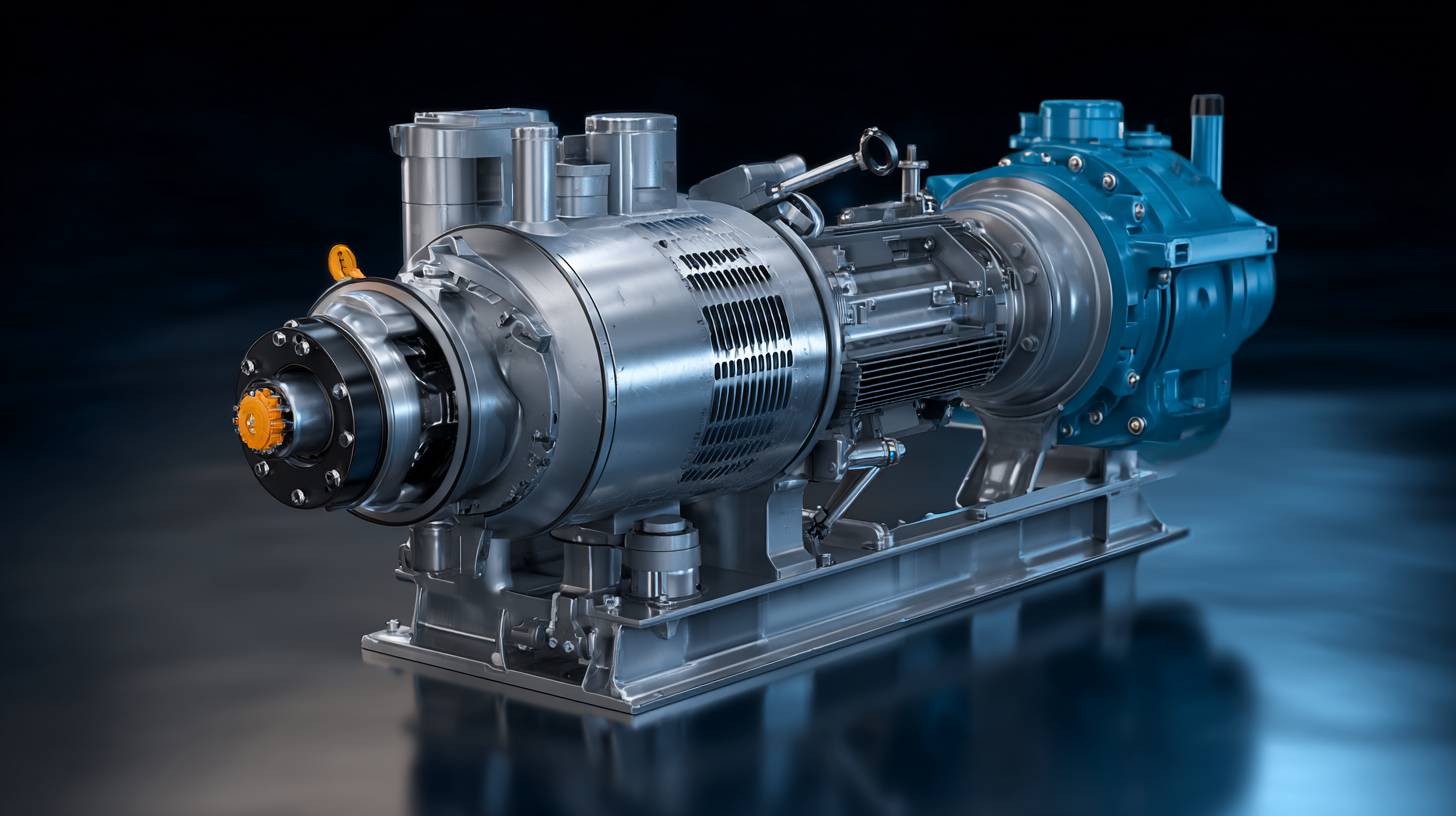

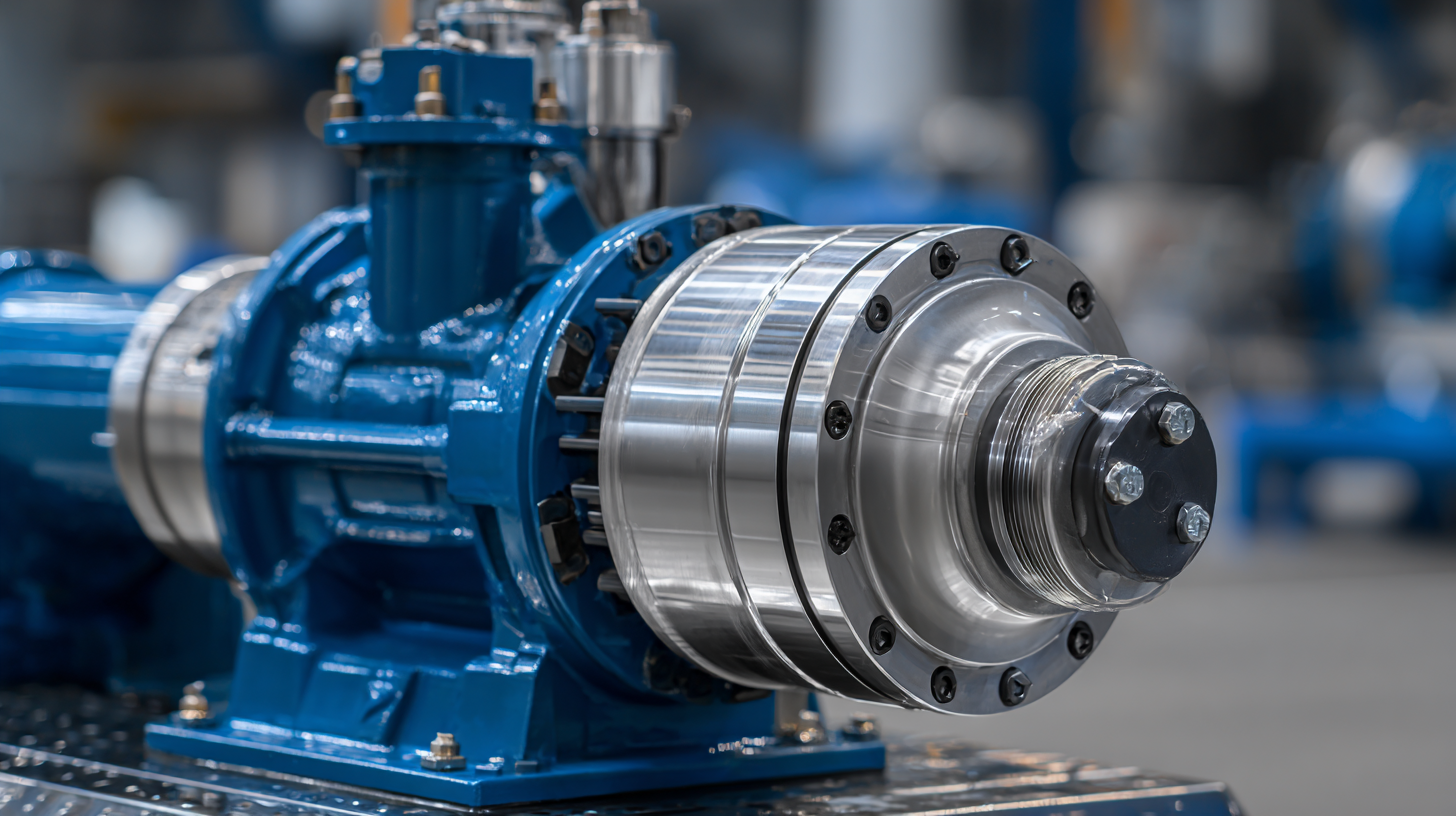

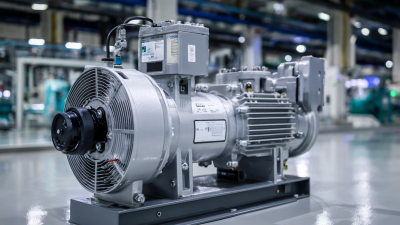

Understanding the functionality of high pressure slurry pumps involves examining their key components and principles of operation. Typically, they consist of a motor, impeller, and casing, all engineered to withstand the harsh environments they often operate in. The impeller plays a pivotal role in creating the necessary pressure differential to move the slurry, while the casing is designed to contain the flow and minimize wear from abrasive particles. This technology not only enhances productivity but also reduces maintenance costs, making high pressure slurry pumps indispensable tools for industries aiming to optimize their operational efficiency.

High pressure slurry pumps have become essential in modern industrial processes, offering significant advantages that enhance operational efficiency. Their ability to handle high viscosity and particulate-laden fluids allows them to excel in industries such as mining, construction, and wastewater treatment. According to recent industry analyses, the global market for high pressure slurry pumps is projected to experience substantial growth, driven by the need for more effective material handling solutions in these demanding environments.

One of the key advantages of high pressure slurry pumps is their robustness and durability, which ensure reliable performance under extreme conditions. These pumps can handle pressures above 100 psi, making them ideal for transporting abrasive and corrosive materials over long distances. Furthermore, advancements in pump design and technology have led to better energy efficiency, minimizing operational costs and environmental impact. As noted in the latest market reports, the rise in infrastructure projects and increasing demand for mining resources are anticipated to further propel the uptake of high pressure slurry pumps, establishing them as a cornerstone in industrial applications.

Efficiency metrics are crucial in assessing the impact of slurry pumping systems on industrial processes. The mining industry, a key player in supplying raw materials, has seen significant advancements in slurry pump technology that contribute to operational efficiency. Recent studies highlight the importance of integrating predictive maintenance strategies, which utilize advanced software to analyze data, reduce unplanned downtime, and enhance overall system performance. This proactive approach not only optimizes the life span of slurry pumps but also ensures consistent productivity in mining operations.

Tips: When considering efficiency metrics, focus on key performance indicators such as pump uptime, maintenance schedules, and energy consumption. Regularly monitor these metrics to identify trends and make informed decisions that can lead to significant cost savings.

Moreover, innovations like IoT wear sensors and numerical modeling are paving the way for better predictions of slurry pump wear evolution, underscoring the necessity of real-time monitoring and management. With autonomous control systems emerging as more effective measures than simple uptime tracking, industries can move towards a more dynamic approach to performance evaluation, ensuring that every aspect of the slurry transport process contributes to higher efficiency and sustainability.

| Metric | Value | Unit | Impact |

|---|---|---|---|

| Pump Efficiency | 85 | % | Reduces energy consumption |

| Flow Rate | 2000 | m³/h | Increases production capacity |

| Operational Cost | $5000 | /month | Improves ROI |

| Maintenance Frequency | 6 | months | Reduces downtime |

| Total Operating Hours | 2000 | hours/year | Increases service life |

High pressure slurry pumps play a crucial role in various industrial processes, where efficiency is key to optimizing operations. Understanding best practices for maintenance and operation is essential to ensure longevity and reliability. According to a report by the Mining Magazine, improper maintenance can lead to a 25% decrease in pump efficiency and significantly increase operational costs. Regular inspections and adherence to manufacturer guidelines can help mitigate these risks, extending pump life and enhancing performance.

Routine maintenance practices include regular lubrication of bearings, monitoring for wear and tear, and ensuring proper alignment of the pump and motor. A study published in the Journal of Hydraulic Engineering indicated that proactive maintenance can reduce unplanned downtime by up to 30%, equating to substantial savings for industrial operations. Additionally, implementing condition monitoring technologies allows for real-time analysis, enabling operators to address issues before they escalate, further enhancing the reliability of slurry pumps. By focusing on these best practices, industries can harness the full potential of high pressure slurry pumps, considerably improving their operational efficiency.

High pressure slurry pumps are at the forefront of revolutionizing industrial processes through innovative technologies that enhance efficiency and productivity. Recent studies indicate that these pumps can achieve efficiencies exceeding 85%, significantly reducing energy consumption compared to traditional pumping systems. For instance, the Global Slurry Pumps Market Report 2023 estimates that implementing advanced materials and designs has led to a 25% increase in operational lifespan, thus decreasing maintenance costs and minimizing downtime for industries such as mining, construction, and wastewater treatment.

The design advancements in high pressure slurry pumps include the use of wear-resistant materials and optimized hydraulic profiles, which enable them to handle aggressive slurries with greater reliability. According to the Market Research Future report, the demand for high pressure slurry pumps is projected to grow at a CAGR of 6.92% from 2021 to 2028, driven by the increasing need for efficient material handling solutions. Innovative features, such as smart monitoring systems, also allow for real-time assessment of pump performance, ensuring optimal operation and reducing the risk of failures. These technologies not only enhance operational efficiency but also contribute to sustainability goals by lowering the carbon footprint associated with industrial processes.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.