Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

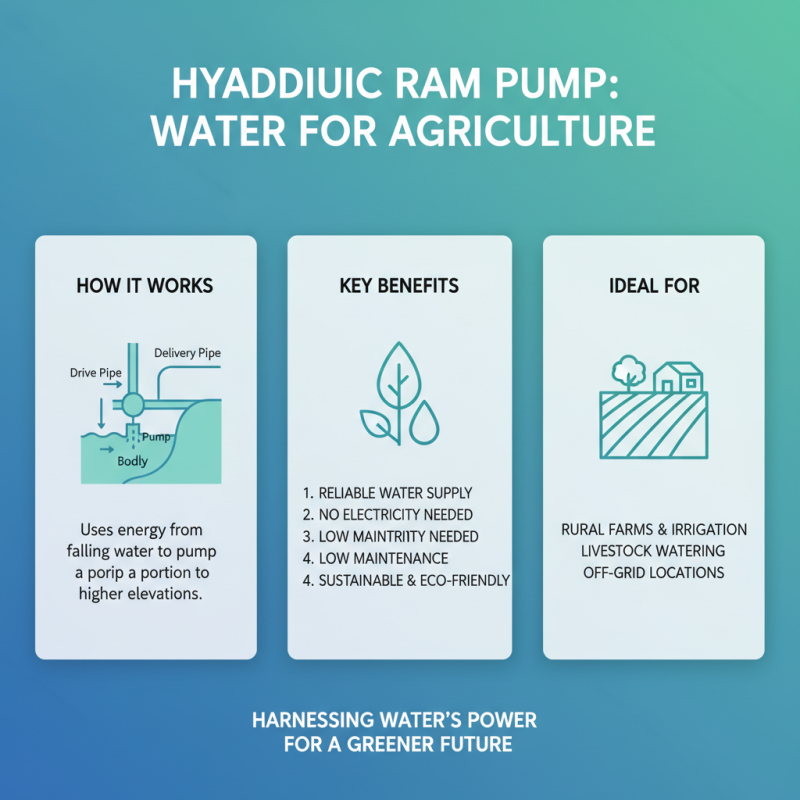

A hydraulic ram pump is an innovative water-lifting device that harnesses the power of flowing water to elevate it without the need for external energy sources. This sustainable technology utilizes the kinetic energy of a stream or river to generate a hydraulic pressure, enabling the movement of water to higher elevations. As communities increasingly seek efficient solutions for irrigation, livestock watering, and potable water supply, the hydraulic ram pump emerges as a viable option for those looking to utilize natural water sources effectively.

Understanding how a hydraulic ram pump operates is crucial for determining its applicability to various water needs. The pump works through a cycle of water flow, utilizing a valve system that creates pressure and allows a portion of the input water to be pushed to a higher location. This unique mechanism not only minimizes energy consumption but also maximizes efficiency in water lifting. By studying the principles behind the hydraulic ram pump, users can appreciate its role in sustainable water management and its potential benefits in rural and remote areas where traditional pumping methods may be impractical or costly.

The hydraulic ram pump is an ingenious device that leverages the principles of water hammer to elevate water to higher elevations without the need for external power. Dating back to the early 18th century, this pump was first developed in France and quickly gained popularity for its efficiency and practicality in rural irrigation systems. Its design is simple yet effective, allowing it to harness the kinetic energy of flowing water, typically from a stream or river, to pump a fraction of that water to a desired height.

The historical significance of the hydraulic ram pump lies in its revolutionary approach to water management. Before the advent of electricity and modern pumping systems, this pump provided a sustainable solution for farmers and communities, enabling them to access water from elevated sources. Its longevity and ease of maintenance have kept it relevant, even in contemporary agricultural practices, where reliance on renewable energy and low-cost solutions is paramount.

Tip: When considering the installation of a hydraulic ram pump, assess the flow rate and available head of your water source to determine its suitability. Additionally, regular maintenance checks can ensure that your pump operates efficiently for years to come. Understanding the historical context of such devices can also provide insight into their practical applications today, highlighting the blend of innovation and nature in solving water accessibility challenges.

A hydraulic ram pump is a unique device that utilizes the principles of the water hammer effect to move water to higher elevations without the need for external power sources. This innovative mechanism relies on the sudden closing of a valve, causing a shock wave that increases water pressure. As the water flow is abruptly halted, a surge of pressure is created, pushing some of the water into an elevated delivery pipe while the rest continues back to the source. Understanding this principle is key to effectively utilizing a hydraulic ram pump for your water needs.

When considering the implementation of a hydraulic ram pump, it’s essential to assess your water source's flow rate and the required lift. The efficiency of the pump diminishes if the water flow is too low or too high. Regular maintenance is also crucial; ensure that the valve and pump components remain free from debris to operate smoothly.

Tips: Observe the flow characteristics of your water source for a few days before installation, as this can significantly influence the pump's performance. Additionally, consider the angle and length of the delivery pipe, as these factors play a role in optimizing water flow and pressure. With the right setup, a hydraulic ram pump can be a sustainable and effective solution to meet your water supply needs.

| Feature | Description |

|---|---|

| Pump Type | Hydraulic Ram Pump |

| Operating Principle | Uses water hammer effect to pump a portion of water to a higher elevation. |

| Input Water Source | Stream, river, or any flowing water source. |

| Output Water Delivery | Typically delivers water to an elevation of 10-20 times the fall height. |

| Energy Source | Gravitational potential energy of falling water. |

| Maintenance Requirement | Low; mainly involves checking seals and water supply. |

| Key Component | Delivery valve, waste valve, and pressure chamber. |

| Applications | Irrigation, livestock water supply, off-grid water systems. |

| Advantages | Energy-efficient, sustainable, low operational costs. |

A hydraulic ram pump is a remarkable device that harnesses kinetic energy from flowing water to lift a portion of that water to a higher elevation, making it particularly useful in remote locations without electricity. The key components of a hydraulic ram pump include the drive pipe, waste valve, delivery pipe, and air chamber, each playing a crucial role in the pump's functionality.

The drive pipe, typically made of sturdy materials, channels the incoming water from a lower source. As water flows through this pipe, it gains kinetic energy, which is essential for the pump's operation. When the water reaches the waste valve, it creates a sudden pressure that causes the valve to close rapidly. This closure is a pivotal moment that triggers the transfer of energy, allowing a portion of the water to be forced through the delivery pipe and into the storage tank. A report by the International Water Management Institute (IWMI) highlights that hydraulic ram pumps can efficiently lift water to heights of up to 100 meters, utilizing the energy created in this process.

The air chamber, another critical component, serves to stabilize the water flow and facilitate efficient operation. It absorbs the shockwave created when the waste valve closes and helps maintain a consistent pressure, promoting smoother water delivery. The air chamber's capacity can significantly impact performance, as research indicates that the optimal size can enhance efficiency by up to 30%. Understanding these components and their functions allows for better implementation of hydraulic ram pumps, providing sustainable water solutions tailored to diverse agricultural and domestic needs.

Hydraulic ram pumps are innovative devices that utilize the energy from falling water to pump a smaller volume of water to a higher elevation. This mechanism makes them particularly beneficial in agricultural settings where reliable water supply is essential for crop production. Once installed, these pumps require little maintenance, making them ideal for rural areas lacking access to conventional water systems.

In agriculture, hydraulic ram pumps can efficiently transport water from streams or rivers to irrigation systems, ensuring that crops receive the necessary hydration without the need for electric or fuel-powered pumps. Additionally, they contribute to sustainable farming practices by leveraging renewable energy sources. Beyond agriculture, these pumps can also be utilized for rural water supply in communities, providing fresh water for drinking and sanitation without relying on external energy inputs. By tapping into local water sources, hydraulic ram pumps enhance water accessibility and promote self-sufficiency in rural areas.

Hydraulic ram pumps offer a unique solution for those needing a sustainable and efficient means of water transportation. One of the primary advantages of hydraulic ram pumps is their ability to operate without electricity or fuel, making them an eco-friendly choice for remote areas where conventional power sources are unavailable. They function by utilizing the kinetic energy of flowing water, allowing them to lift water to heights that can be several times the height of the source, thereby facilitating water access where gravity-fed systems might fail.

However, there are limitations to consider when implementing hydraulic ram pumps. They require a continuous flow of water in the source to function effectively, which can be a challenge in periods of drought or low water availability. Additionally, while they are generally low-maintenance, the initial installation can be complex, requiring precise calculations of flow rates and lift heights. Furthermore, hydraulic ram pumps may not be ideal for all applications, particularly where a large volume of water needs to be delivered quickly, as they are designed for efficiency rather than high output. Understanding these advantages and limitations is essential for users considering hydraulic ram pumps to meet their water needs.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.