Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

Selecting the appropriate sludge pump is crucial for effective wastewater management. Sludge pumps play a vital role in transporting thick, viscous materials from various treatment processes, ensuring that operations run smoothly and efficiently. With a wide range of options available, choosing the right pump can significantly impact the overall efficiency and reliability of wastewater systems.

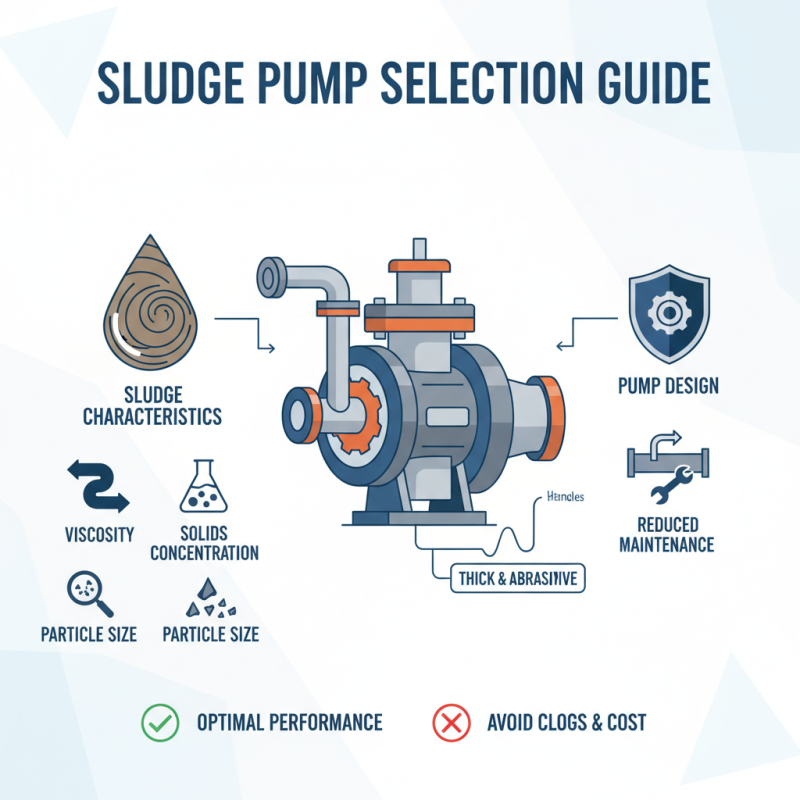

When considering the selection of sludge pumps, several factors come into play, including the type of sludge, flow rate, and pump construction material. Understanding the specific requirements of your wastewater treatment facility will enable you to make informed decisions that optimize performance while minimizing maintenance costs. Moreover, advancements in pump technology are continually evolving, providing new opportunities for improved efficiency and effectiveness in dealing with sludge.

In this guide, we will explore the key considerations and criteria necessary for selecting the right sludge pump tailored to your wastewater management needs. By focusing on the operational demands and characteristics of the sludge being handled, you can ensure the longevity and reliability of your pumping system, ultimately contributing to a more sustainable and effective wastewater treatment process.

When choosing the right sludge pump for wastewater management, it's crucial to understand the various types available, as they cater to different needs and conditions. Among the most common types are centrifugal, positive displacement, and screw pumps. Centrifugal pumps are widely used in many applications due to their efficiency and ability to handle large volumes of fluid. They are particularly effective for transporting low-viscosity sludge and are favored in municipal wastewater treatment facilities. According to a recent industry report, centrifugal pumps account for approximately 60% of the global sludge pump market, owing to their reliability and cost-effectiveness.

On the other hand, positive displacement pumps, which include diaphragm and rotary lobe styles, are ideal for handling thick, viscous sludge. These pumps operate by trapping a fixed amount of sludge and forcing it through the discharge pipe, making them suitable for more challenging environments where sludge consistency can vary significantly. Reports indicate that the usage of positive displacement pumps has been increasing, especially in industrial applications where higher sludge densities are common. Additionally, screw pumps are gaining traction for their ability to handle slurries with large solids, providing gentle pumping action that minimizes shear and degradation of the materials being transported. As the wastewater treatment industry continues to evolve, selecting the appropriate sludge pump type will be pivotal to ensuring operational efficiency and environmental compliance across diverse applications.

When selecting the right sludge pump for your wastewater management needs, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, understanding the characteristics of the sludge being pumped is crucial. Sludge can vary significantly in terms of viscosity, solids concentration, and particle size. For example, according to a report by the Water Environment Federation, sludge with high solids content typically requires a pump designed for dense and abrasive materials. Choosing a pump capable of handling these characteristics will help prevent clogs and reduce maintenance costs.

Another important factor is the pump's capacity and flow rate, which should align with the specific demands of your wastewater treatment process. The Hydraulic Institute recommends selecting a pump with a flow rate that matches the anticipated throughput to minimize the risk of overloading or underutilization. Additionally, consider the application's operating environment, including temperature and potential exposure to chemicals, as these conditions can impact the pump’s materials and design.

**Tips:** When evaluating potential pumps, consult with manufacturers about the compatibility of materials with your specific sludge type to extend the equipment's lifespan. Additionally, consider the total cost of ownership by factoring in maintenance and energy consumption. Doing so will ensure that you make a well-informed decision that balances performance with economic efficiency.

When selecting the right sludge pump for wastewater management, evaluating performance metrics is crucial to ensure efficiency and reliability. Key performance indicators include flow rate, head pressure, and solids handling capability. The flow rate indicates how much sludge the pump can move within a specific time frame, and it is essential to match this with the demands of the wastewater facility. Head pressure, on the other hand, determines how high the pump can lift the sludge, impacting its ability to discharge waste over varying distances.

Another important metric is the solids handling capability, which refers to the size and concentration of solids the pump can transport without clogging or damaging the system. This is particularly relevant in wastewater applications, where varying sludge characteristics can pose challenges. Assessing these performance metrics not only aids in selecting a pump that can effectively handle the specific conditions of the wastewater facility but also helps in minimizing maintenance costs and maximizing operational efficiency. By carefully evaluating these parameters, operators can ensure that the chosen sludge pump will meet their wastewater management needs effectively.

When selecting a sludge pump for wastewater management, understanding the maintenance requirements and expected lifespan is crucial. According to a report by the Water Environment Federation (WEF), the average operational lifespan of a well-maintained sludge pump ranges from 8 to 15 years, heavily influenced by the type of sludge, operational conditions, and the quality of maintenance practices implemented. Regular maintenance, including routine inspections and parts replacements, can significantly extend this lifespan, reducing the overall lifetime costs of pump ownership.

Maintenance requirements vary based on the pump type and application. Submersible pumps, for instance, may necessitate more frequent checks for wear on seals and impellers, typically every 6 to 12 months, while positive displacement pumps may require less frequent maintenance intervals, though they demand regular monitoring of hydraulic performance. An analysis by the International Water Association (IWA) suggests that facilities implementing preventive maintenance routines can reduce unplanned repair costs by up to 50%. Additionally, investing in pumps designed with easy access for repairs can further simplify maintenance tasks, directly impacting the downtime associated with pump inefficiencies or failures.

When budgeting for sludge pump acquisition, it's crucial to consider both initial costs and long-term expenses. The purchase price of a sludge pump can vary based on its capacity, material, and technology. However, buyers should keep in mind that the lowest initial cost may not necessarily lead to the best value. Factors such as energy efficiency, maintenance requirements, and durability will heavily influence operational costs over time. Investing in a pump with a higher upfront cost may result in significant savings in energy bills and maintenance in the long run.

Moreover, understanding the total cost of ownership is vital for effective budgeting. This includes not only the purchase price but also the installation costs, potential downtime for repairs, and ongoing maintenance expenses. It's essential to evaluate the expected lifespan of the pump and factor in depreciation. By considering these elements, facility managers can develop a more accurate budget that reflects the true financial impact of their sludge pump choice. Planning for these costs ensures that organizations can maintain consistent wastewater management without unexpected financial burdens.

| Pump Type | Flow Rate (GPM) | Head (FT) | Power (HP) | Initial Cost ($) | Annual Maintenance Cost ($) | Expected Lifespan (Years) |

|---|---|---|---|---|---|---|

| Submersible Pump | 300 | 40 | 5 | 2500 | 300 | 10 |

| Centrifugal Pump | 400 | 30 | 7.5 | 3200 | 350 | 12 |

| Positive Displacement Pump | 250 | 50 | 10 | 4000 | 400 | 8 |

| Diaphragm Pump | 200 | 20 | 3 | 1500 | 250 | 15 |

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.