Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

When it comes to maintaining a clean and healthy environment, choosing the right filtration pump is essential. Filtration pumps are critical in various applications, from aquariums and swimming pools to industrial processes and aquaculture. With an overwhelming number of options available in the market, making the right choice can be daunting. Understanding your specific needs and the features available in different types of filtration pumps will help streamline your decision-making process.

In this article, we will explore the top ten tips for selecting the filtration pump that best suits your requirements. Each tip will provide valuable insights into factors such as flow rate, compatibility, and maintenance, ensuring that you make an informed decision. By considering these important aspects, you can enhance the efficiency and longevity of your filtration system, ultimately contributing to cleaner water and a more sustainable environment. Whether you are a hobbyist or a professional, mastering the art of choosing the right filtration pump is a vital step towards achieving optimal performance in your endeavors.

When selecting a filtration pump, understanding the different types available is crucial to making the right choice for your specific needs. Filtration pumps come in various configurations, including centrifugal, submersible, and positive displacement pumps, each designed for different applications.

Centrifugal pumps are ideal for larger systems where high flow rates are necessary, commonly used in swimming pools or industrial settings. They operate by converting rotational energy into flow, making them efficient for moving water through filters.

Submersible pumps, on the other hand, are designed to operate underwater, making them suitable for applications requiring the removal of water from deep areas like basements or ponds. They are typically more compact and can handle various types of fluids, including those with sediment.

Positive displacement pumps provide a consistent flow rate by trapping a fixed volume of fluid and forcing it through the discharge, making them perfect for applications requiring precise dosing such as in aquariums or chemical processing.

In addition to these types, it's important to consider factors such as the pump's capacity, power source, and durability when making your selection. Assessing the specific requirements of your filtration system will guide you in choosing a pump that not only fits your needs but also ensures efficient and effective filtration.

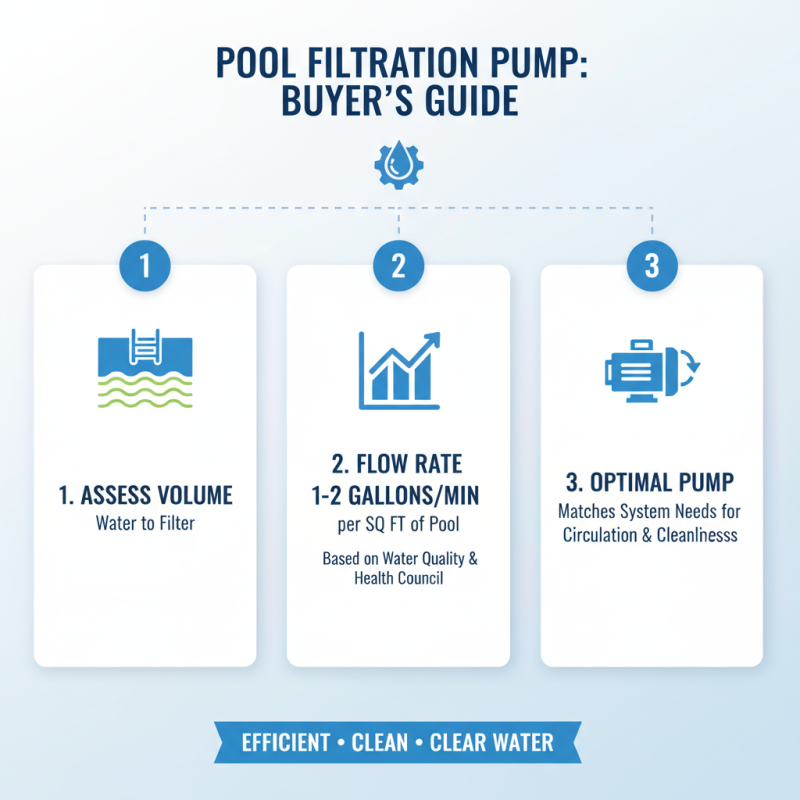

When choosing a filtration pump, understanding your specific filtration needs and requirements is crucial for optimal performance and efficiency. Start by assessing the volume of water you need to filter. According to the Water Quality and Health Council, maintaining water quality in residential pools can require filtering at a rate of at least 1 to 2 gallons per minute for every square foot of surface area. This statistic underscores the importance of selecting a pump that can handle your particular system's demands, ensuring that water is effectively circulated and contaminants are minimized.

Next, consider the specific contaminants you wish to address. The Environmental Protection Agency's (EPA) guidelines recommend tailoring filtration systems to the particular impurities present in your water supply. For instance, if you're dealing with sediment or larger particulate matter, a pump with a coarser filter may suffice, whereas finer contaminants such as bacteria may necessitate a much different filtration approach. Thus, evaluating the water quality through testing and determining which filtration standards align with your requirements can significantly impact your selection process. Additionally, it’s essential to factor in energy consumption and maintenance needs of your chosen pump, as these elements can help in both cost savings and ensuring long-term operational sustainability.

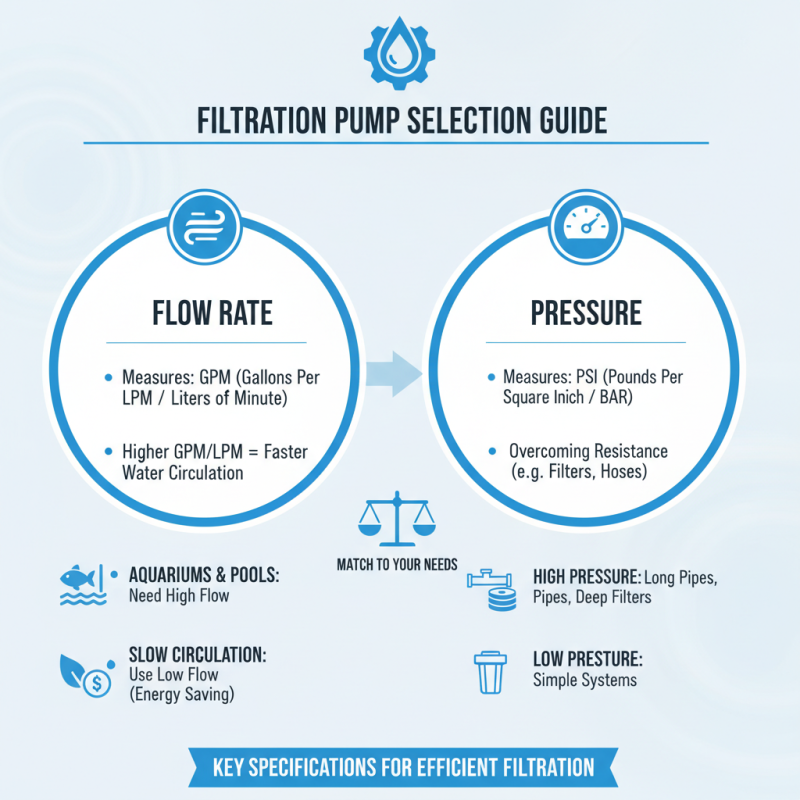

When selecting a filtration pump, understanding the specifications, particularly flow rate and pressure, is crucial for ensuring that the pump meets your specific needs. The flow rate indicates how much water the pump can move per minute, typically measured in gallons per minute (GPM) or liters per minute (LPM). A higher flow rate means that the pump can circulate water more quickly, which is essential for applications requiring rapid filtration, such as aquariums or swimming pools. Conversely, if your system does not need rapid circulation, a lower flow rate may suffice and can help save on energy costs.

Pressure is another vital factor to consider. It reflects the force the pump exerts to push water through the filtration system, typically measured in pounds per square inch (PSI) or bars. Suitable pressure levels are necessary to maintain adequate water movement and ensure that the filtration media operates effectively. If the pressure is too low, contaminants may not be adequately filtered out, leading to water quality issues. Conversely, excessive pressure can damage the filtration system or lead to unnecessary wear and tear. Thus, evaluating both the flow rate and pressure allows you to select a pump that will provide optimal performance tailored to your specific filtration requirements.

When selecting a filtration pump, material quality and durability are critical factors that significantly impact performance and longevity. A 2021 industry report highlighted that pumps constructed from high-grade materials, such as corrosion-resistant alloys or high-density polyethylene, offer superior resistance to wear and tear, particularly in harsh environments. For instance, pumps made with stainless steel can withstand temperatures and pressures beyond the capabilities of standard plastic models, extending their operational lifespan by up to 50%. Thus, understanding the material composition can guide consumers in making informed decisions that align with their specific application needs.

Furthermore, the durability of filtration pumps is often tied to their design and the quality of their components. Reports indicate that pumps featuring reinforced housings and seals are less prone to leakage and breakdown, which is essential for maintaining efficiency in filtration systems. According to the American Society of Mechanical Engineers, properly selected pumps can reduce maintenance costs by 30% over their lifecycle, emphasizing the importance of investing in durable options. When evaluating different filtration pumps, it is advisable to consider both the material quality and the engineering aspects that contribute to the overall resilience of the product, ensuring long-term satisfaction and reduced operational disruptions.

When selecting the right filtration pump, considering ease of maintenance and the availability of replacement parts is crucial for ensuring long-term efficiency and functionality. According to the 2021 Industrial Pump Report, nearly 57% of maintenance issues arise from outdated or unavailable replacement components. This data illustrates that opting for a filtration pump from a manufacturer with a robust supply chain can significantly reduce downtime, ultimately leading to cost savings.

Moreover, routine maintenance plays a vital role in the lifespan of filtration pumps. A study conducted by the American Society of Mechanical Engineers (ASME) found that pumps that are easier to maintain can provide up to 30% longer service life compared to those requiring complex servicing. When choosing a filtration pump, it is advisable to review the maintenance protocols and assess how accessible the replacement parts are. Engaging with suppliers who clearly outline part replacement timelines and accessibility will also enhance your operational efficiency and prevent unexpected interruptions.

| Tip Number | Tip | Ease of Maintenance | Replacement Parts Availability |

|---|---|---|---|

| 1 | Assess Your Filtration Needs | Moderate | High |

| 2 | Check Pump Specifications | Easy | Medium |

| 3 | Look for Energy Efficiency | Easy | High |

| 4 | Consider Noise Levels | Moderate | Medium |

| 5 | Evaluate Build Quality | Difficult | High |

| 6 | Ensure Safety Features | Easy | Medium |

| 7 | Research Manufacturer Reputation | Moderate | High |

| 8 | Ask About Warranty Options | Easy | Medium |

| 9 | Verify Support and Customer Service | Moderate | High |

| 10 | Compare Pricing | Easy | Medium |

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.