Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In today's diverse world of fluid management, selecting the right universal pump can be a crucial decision for various applications. Universal pumps are designed to cater to a wide range of fluids, which makes them a versatile option for both industrial and residential use. Whether you need to transfer water, chemicals, or other liquids, understanding the specifications and capabilities of different universal pump models can help ensure you choose the most suitable one for your needs.

As we delve into the top ten universal pumps available on the market, it is essential to consider factors such as flow rate, material compatibility, and energy efficiency. Each pump has its unique features that may align perfectly with specific applications or requirements. In this guide, we aim to provide insights that will simplify your selection process, helping you navigate through the options and find the universal pump that best meets your pumping needs. Ultimately, the goal is to empower users with knowledge, enabling them to make an informed decision in a sea of choices.

Universal pumps are versatile devices designed to handle various fluids across multiple industries, from agriculture to manufacturing. Their adaptability primarily stems from their different designs, including centrifugal, positive displacement, and gear pumps. Each type is suited for specific applications based on factors such as fluid viscosity, flow rate, and pressure requirements. According to recent industry reports, the global market for universal pumps is anticipated to grow at a CAGR of 5.6% from 2021 to 2028, reflecting their increasing importance in operational efficiency and fluid management.

Centrifugal pumps are the most commonly used universal pumps, making up over 70% of the market, especially favored for their ability to move large volumes of low-viscosity fluids like water and chemicals. In contrast, positive displacement pumps, while accounting for around 20% of the market, excel in transferring high-viscosity fluids, ensuring a consistent flow regardless of changes in pressure. Gear pumps, a subtype of positive displacement pumps, have seen a 15% increase in demand within the food and beverage sector due to their ability to maintain product integrity while handling viscous materials. As industries continue to innovate, selecting the right type of universal pump remains crucial for optimizing processes and reducing downtime.

| Pump Type | Application | Max Flow Rate (GPH) | Max Head (Feet) | Power Source |

|---|---|---|---|---|

| Submersible Pump | Well Water, Sewage | 2000 | 30 | Electric |

| Centrifugal Pump | Water Supply, Irrigation | 1500 | 50 | Electric, Gas |

| Peristaltic Pump | Chemical Transfer, Food Processing | 500 | 15 | Electric |

| Diaphragm Pump | Wastewater Treatment, Oil Transfer | 800 | 25 | Electric, Pneumatic |

| Positive Displacement Pump | High Viscosity Fluids, Fuel Transfer | 600 | 40 | Electric, Hydraulic |

| Gear Pump | Lubrication, Fuel Handling | 700 | 20 | Electric, Mechanical |

| Vacuum Pump | Packaging, Laboratory | 400 | 10 | Electric |

| Hydraulic Pump | Construction, Automotive | 300 | 60 | Hydraulic |

| Screw Pump | Heavy Oil, Sludge | 850 | 35 | Electric |

| Fountain Pump | Garden, Outdoor Decor | 250 | 15 | Electric |

When selecting a universal pump, it’s essential to consider several key features that align with your specific requirements. First, the pump’s flow rate is a critical factor that determines its efficiency and ability to meet your demands. Flow rate, often measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move in a given time. Assessing your project's needs will help you choose a pump that provides the optimal flow without being overworked or underperforming.

Another important consideration is the pump's material and compatibility with the fluids being handled. Different materials, such as stainless steel, plastic, or bronze, offer varying levels of resistance to corrosion and wear. If you are pumping harsh chemicals or abrasive substances, selecting a pump made from durable materials that can withstand those conditions is crucial. Additionally, evaluating the type of mechanism—whether it's positive displacement or centrifugal—will impact the performance and efficiency of the pump in various applications. Understanding these aspects will lead to a well-informed decision that meets your needs effectively.

When selecting a universal pump, it's essential to understand the various specifications and features available in the market. Universal pumps are designed for a broad range of applications, making them versatile tools for both industrial and residential use. Key specifications to consider include flow rate, pressure output, and the type of fluid being handled. Flow rate is crucial as it determines how quickly a pump can move fluid from one point to another. Higher pressure output may be necessary for more demanding applications, while the pump material must be compatible with the fluids to ensure longevity and reliability.

Another critical aspect is the pump's design and ease of maintenance. Many universal pumps come with various configuration options that cater to specific needs, such as submersible or non-submersible designs, which can greatly influence operational efficiency. Look for features like adjustable speed settings and built-in controllers that allow for fine-tuning performance based on varying operational conditions. By carefully analyzing these specifications, you can choose a universal pump that not only meets your immediate requirements but also adapts to future needs, ensuring a sound investment for years to come.

When choosing the right universal pump, understanding the performance and efficiency of various models is crucial. The first aspect to consider is the flow rate, which indicates the volume of fluid the pump can move within a certain timeframe. Higher flow rates often mean quicker operation, but they may come at the cost of increased energy consumption. Conversely, models with lower flow rates may conserve energy but take longer to accomplish the same task. Analyzing the specific needs of your application—be it in agricultural, industrial, or residential settings—will help determine the most suitable balance between flow rate and energy efficiency.

Another critical factor in the comparative analysis of universal pumps is their tolerances to different fluid types and conditions. Some pumps excel in handling corrosive liquids, while others are designed for thicker materials. This versatility can significantly impact overall system reliability and maintenance. Additionally, considering the design and technology behind the pump can offer insights into its longevity and operational costs. Opting for a model that boasts advanced energy-saving technologies can lead to lower long-term expenses, making it a wise investment. Evaluating these aspects will enable users to select a pump that not only meets their immediate requirements but also aligns with their long-term operational goals.

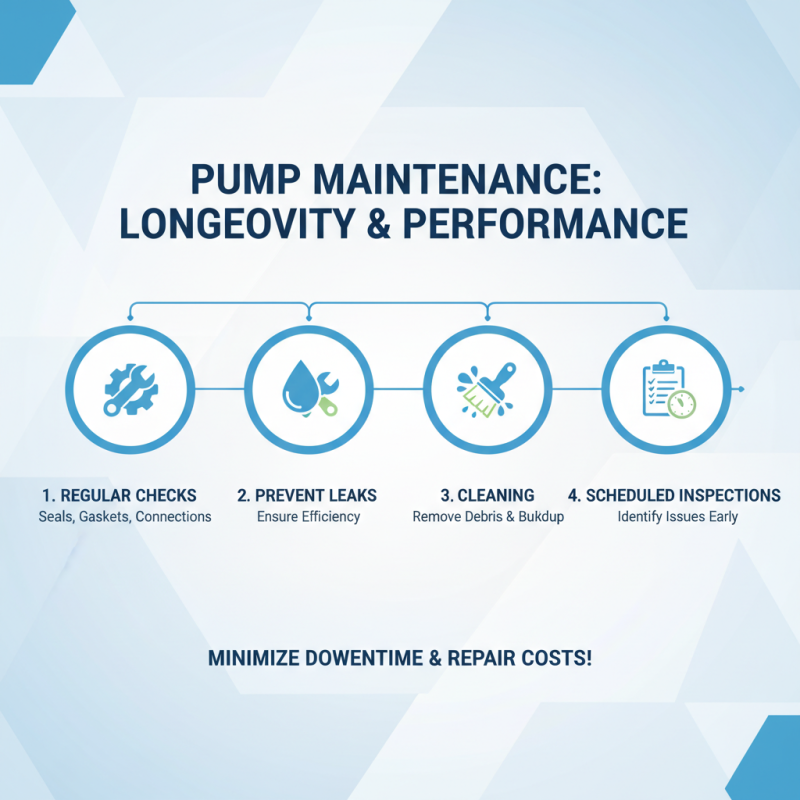

Maintaining a pump is crucial for ensuring its longevity and optimal performance. Regular maintenance practices such as checking seals, gaskets, and connections can prevent leaks and ensure that the pump operates efficiently. Additionally, cleaning the pump and its components regularly helps to remove any debris or buildup that could hinder performance. Implementing a scheduled inspection routine allows users to identify potential issues before they escalate into more significant problems, minimizing downtime and repair costs.

Another essential aspect of pump maintenance is monitoring performance indicators. Keeping an eye on the pump's pressure and flow rates can help detect irregularities that may indicate wear or malfunction. Furthermore, lubrication of moving parts is necessary to reduce friction, which not only enhances efficiency but also prolongs the life of the pump. Lastly, ensuring that the pump is installed in a suitable environment, protected from extreme temperatures and moisture, can significantly extend its operational lifespan. By following these tips, users can maximize their pump's efficiency and durability, ultimately leading to better performance over time.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.