Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the evolving landscape of industrial manufacturing, diaphragm presses have emerged as a critical tool for achieving optimal efficiency and performance in various applications. According to a recent industry report from the Global Press Association, the market for diaphragm presses is projected to grow by over 5% annually, driven by advancements in design and material technology. With their ability to deliver consistent pressure and uniform results, diaphragm presses have become essential in sectors ranging from pharmaceuticals to food processing.

Expert insights into the diaphragm press industry highlight the importance of embracing best practices for maximum output. John Mathews, a leading figure in materials engineering, notes, “Properly optimized diaphragm press techniques can significantly enhance yield rates while reducing waste, making them indispensable in modern manufacturing.” As businesses increasingly prioritize sustainability and efficiency, mastering diaphragm press techniques stands out as a vital strategy for organizations aiming to stay competitive in a rapidly changing market.

This article delves into the top 10 diaphragm press techniques that can bolster efficiency and performance. By employing these methods, manufacturers can not only improve productivity but also ensure the quality of their outputs, thereby reinforcing their commitment to excellence and sustainability in production processes.

Diaphragm presses are pivotal in various manufacturing processes due to their ability to apply controlled pressure uniformly across materials. This technique not only enhances the quality of the final product but also significantly increases production efficiency. The diaphragm serves as a flexible barrier that ensures consistent pressure application, reducing the risk of defects and variability that can occur with traditional pressing methods. As industries strive for higher standards and lower material wastage, understanding diaphragm press technology becomes crucial for engineers and manufacturers alike.

Moreover, the importance of diaphragm presses extends beyond mere functionality. They are integral in optimizing workflow and resource management within manufacturing settings. By facilitating precise control over the pressing action, diaphragm presses can seamlessly integrate into automated production lines, allowing for higher throughput and reduced operational costs. The adaptability of diaphragm presses makes them suitable for various applications, including the production of composites, ceramics, and metal parts. As manufacturers seek to innovate and enhance their processes, leveraging diaphragm press techniques is essential for maintaining competitiveness in today's fast-paced market.

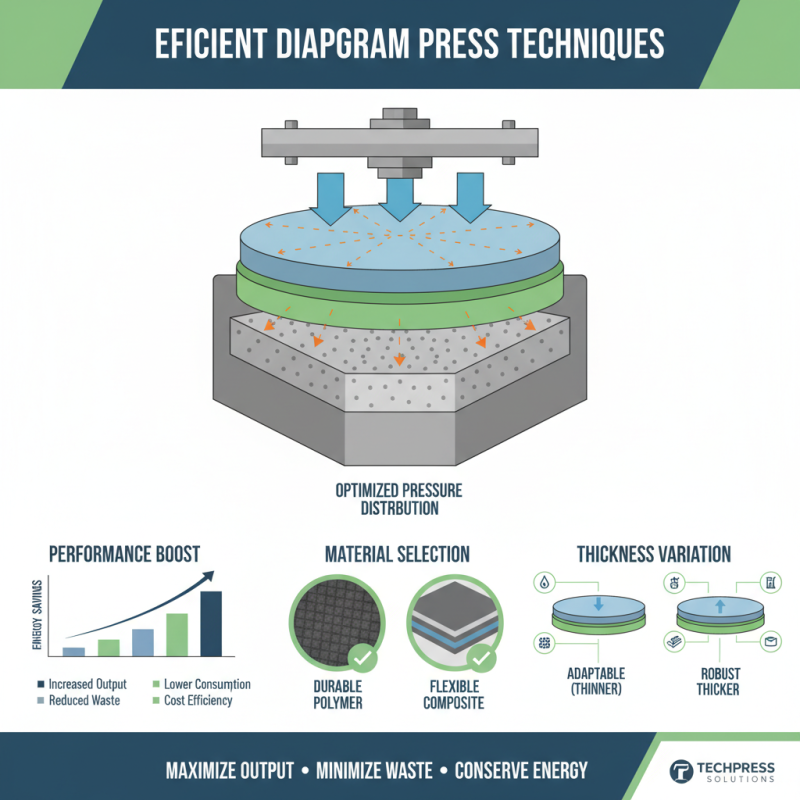

Efficient diaphragm press techniques are grounded in key principles that enhance both performance and energy conservation in various industrial applications. One fundamental principle is the optimization of pressure distribution within the diaphragm. Uniform pressure across the diaphragm ensures a consistent process, maximizing the material output while minimizing waste. Techniques such as proper selection of the diaphragm material and thickness can greatly influence the overall effectiveness, allowing for better adaptability to different processing conditions.

Another crucial aspect is the control of the pressing cycle. Implementing precise timing and pressure settings can lead to enhanced efficiency. By optimizing the pressing duration and force, operators can ensure that materials are processed thoroughly without compromising the integrity or quality. Advanced monitoring systems can aid in maintaining ideal conditions, allowing for real-time adjustments during operation. Emphasizing these key principles not only boosts efficiency but also leads to improved performance and longevity of the diaphragm press equipment, ultimately benefiting production processes across various sectors.

When it comes to maximizing diaphragm press performance, employing effective techniques can significantly enhance both efficiency and output quality. One of the foremost strategies involves maintaining optimal operating conditions. This includes ensuring that the pressure settings are correctly calibrated for the materials being processed, as fluctuations can lead to inconsistent product quality. Regular monitoring and adjustment of the diaphragm’s flexibility and responsiveness result in improved material flow and reduced downtime, ultimately boosting production rates.

Another critical technique is the implementation of routine maintenance and inspection schedules. By systematically servicing the diaphragm press, operators can identify and rectify potential issues before they escalate. This prevents unexpected breakdowns that can disrupt production. Additionally, ensuring proper lubrication of moving components contributes to smoother operation and longevity of the machinery. Training operators to recognize the signs of wear and tear also plays a vital role in maintaining peak performance and preventing costly repairs. By focusing on these practical techniques, facilities can harness the full potential of their diaphragm presses and achieve remarkable results in their production processes.

In the realm of diaphragm press operations, measuring and evaluating efficiency is crucial for optimizing performance. A recent industry report indicated that a well-calibrated diaphragm press can achieve up to 30% greater efficiency compared to an unoptimized setup. This metric highlights the importance of regular assessment and calibration of machinery to maintain peak performance levels. Parameters such as pressure consistency, cycle time, and material yield ratios are essential indicators of efficiency that operators should monitor closely.

Tips: Conduct routine audits of your diaphragm press systems to identify any deviations in performance metrics. Implementing a periodic maintenance schedule can help avoid unexpected downtimes and ensure the machinery operates within its designed parameters.

Moreover, utilizing advanced data analytics tools can provide a deeper insight into operational efficiency. Reports suggest that companies employing predictive analytics in their diaphragm pressing processes have realized increases in overall productivity by approximately 20%. By leveraging real-time data, operators can make informed decisions that lead to improved performance outcomes.

Tips: Invest in data collection and analysis software to gain comprehensive visibility into your diaphragm press operations. This proactive approach not only enhances efficiency but also contributes to long-term cost savings and sustainability in production practices.

This bar chart displays the efficiency ratings of the top 10 diaphragm press techniques. The data indicates the percentage of operational efficiency achieved by each technique, showcasing which methods yield the best performance in diaphragm press operations.

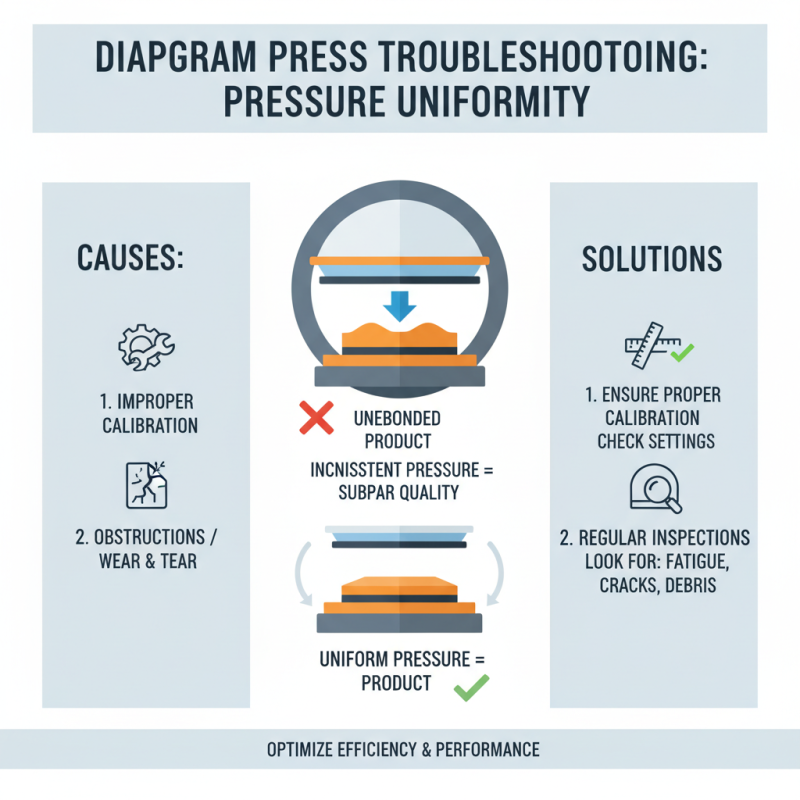

Troubleshooting common issues in diaphragm press processes is essential for maintaining optimal efficiency and performance. One frequent challenge operators face is inconsistent pressure distribution, which can lead to uneven product quality. To address this, it's vital to ensure that the diaphragm is properly calibrated and free of any obstructions or wear. Regular inspections should be performed to check for signs of fatigue or damage in the diaphragm material, as these can compromise the uniformity of pressure application and result in subpar outcomes.

Another common issue is difficulty in achieving the desired throughput due to air entrapment within the system. This can hinder the press's ability to function effectively, leading to longer processing times and increased operational costs. To mitigate this issue, operators should implement efficient venting strategies that allow for the quick release of trapped air. Additionally, using a gradual ramp-up in pressure during the initial stages of the pressing process can help prevent sudden air pockets from forming, reinforcing the overall efficiency of diaphragm presses. Proper maintenance and timely troubleshooting are key to mastering the art of diaphragm pressing and ensuring high performance across all operations.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.