Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the fast-paced food industry, efficiency is crucial. When it comes to transferring liquids, a reliable food transfer pump can make all the difference. According to John Smith, an industry expert, “The right food transfer pump enhances productivity while ensuring safety.” Choosing the right pump aids in minimizing waste and maximizing output.

Food transfer pumps are essential for many operations. They handle various liquids, from oils to sauces. A well-designed pump can reduce downtime and improve workflow. However, not all pumps are created equal. It's important to reflect on performance and efficiency. Some pumps struggle under certain conditions, affecting the quality of the liquid being transferred.

In 2023, careful selection is more pertinent than ever. The latest models offer innovative features, but drawbacks can still exist. Understanding these nuances is key to making an informed decision. A food transfer pump is not just a tool; it is a vital part of the process. Proper evaluation can lead to significant improvements in operations.

Food transfer pumps are vital in liquid handling, especially in the food industry. They ensure efficient movement of various substances, such as oils, juices, or sauces. These pumps reduce waste and improve safety during production. They help maintain hygiene standards by minimizing manual handling. Proper pumps can handle thick or viscous liquids, which is crucial in many food processes.

However, selecting the right pump can be challenging. Different types serve different needs. Compatibility is key, but often overlooked. It's important to understand the properties of the liquids being pumped. For example, some liquids may require special materials to prevent contamination. Maintenance also plays a role in pump efficiency. Neglecting regular checks can lead to failures or inefficiencies.

In practice, not all systems work perfectly. Observing pump performance can reveal many issues. For instance, inconsistent flow rates may hint at underlying problems. Training staff to monitor these aspects is essential. Reflection on these factors can lead to better operational practices. Ultimately, the importance of food transfer pumps goes beyond just moving liquids; they safeguard quality and ensure compliance with industry standards.

This bar chart represents the flow rates of the top 10 food transfer pumps for efficient liquid handling in 2023. Each pump's performance is measured in liters per minute, illustrating their capabilities in food processing applications.

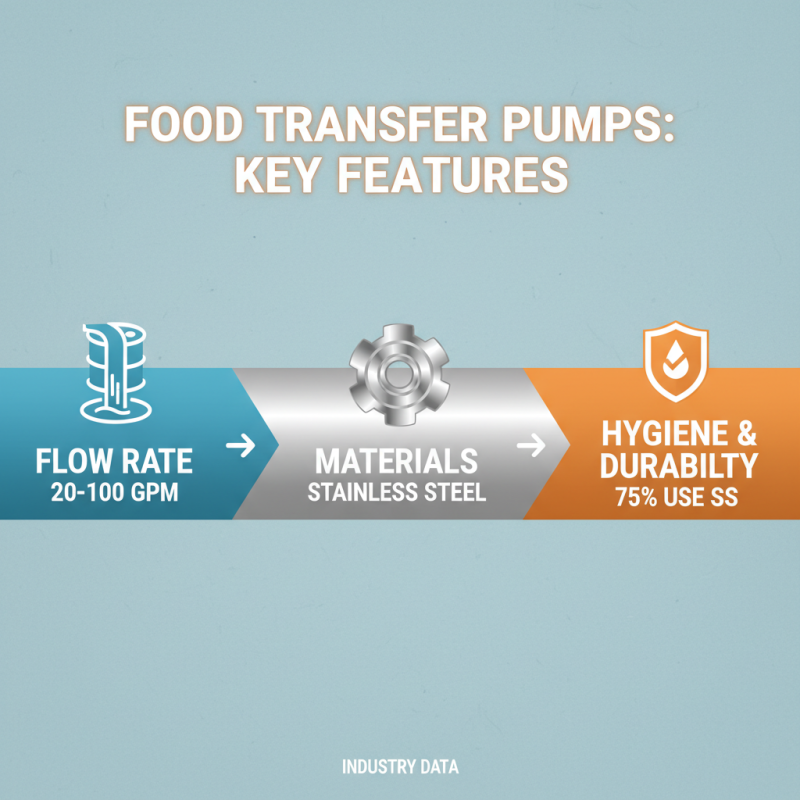

When selecting food transfer pumps, several key features ensure efficient liquid handling. Flow rate is one of the most critical aspects. Ideal pumps deliver between 20 to 100 gallons per minute, depending on the application. A pump's materials are also crucial. Stainless steel enhances hygiene. It resists corrosion and is easy to clean. According to industry data, nearly 75% of food-grade pumps use stainless steel components.

Another vital feature is energy efficiency. Pumps that operate efficiently can reduce energy consumption by up to 30%. Given the rising energy costs, this is significant. Maintenance requirements should not be overlooked. Pumps that are easy to disassemble help avoid long downtimes. A small oversight in parts can lead to costly repairs later.

Many facilities struggle with integrating new technology. Adoption of pumps with smart features may seem daunting. However, these pumps can optimize processes. For instance, real-time monitoring can help detect issues early. While adopting new technology may lead to initial costs, the long-term savings are substantial. In fact, organizations often report a return on investment within 18 months. Efficient food transfer pumps are not just about moving liquids; they play an essential role in the overall productivity of food handling operations.

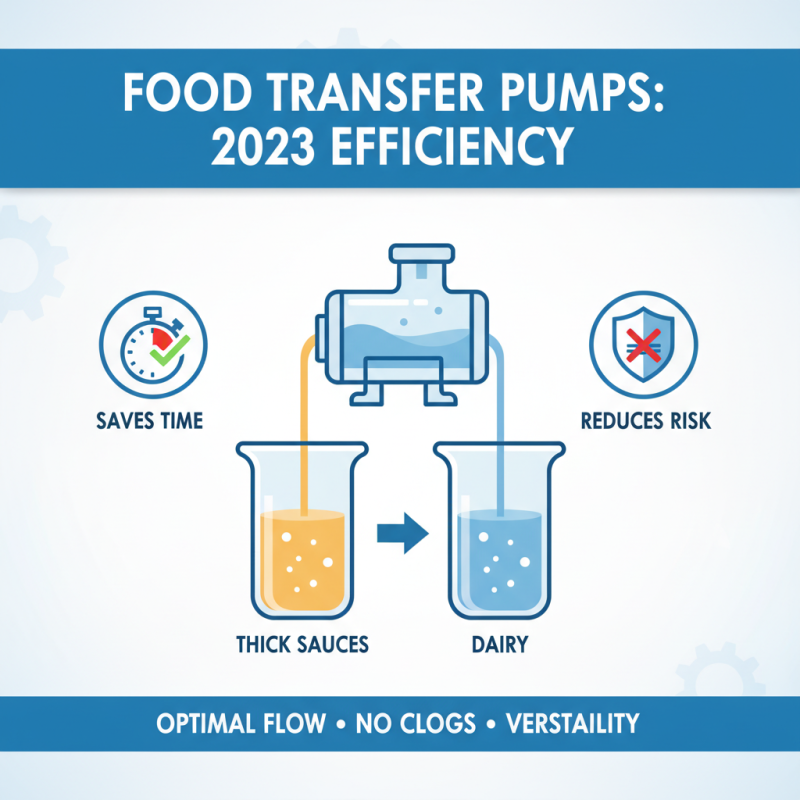

When it comes to food transfer pumps, performance metrics and specifications are crucial. In 2023, efficiency is the name of the game. A good pump should handle various liquids without clogging. For a busy kitchen or food processing plant, this efficiency saves time and reduces risk.

Consider the weight of the pump. Lighter pumps are often easier to handle. Yet, they should still be robust enough for heavy liquids. The ideal pump also has a compact design, allowing easy storage. This can be particularly beneficial in small spaces. Many pumps have flow rate specs that vary significantly. You need pumps that meet specific culinary needs.

Also, pay attention to the ease of cleaning. Sanitary designs are a must for any food handling equipment. If a pump is tough to clean, it can lead to hygiene issues. Some pumps require special tools or disassembly. This can lead to frustration and inefficiency. Users should consider these factors carefully. Choosing the right pump isn’t always straightforward. It’s a decision that needs reflection and understanding of specific needs.

As the food processing industry evolves, so do the technologies that support it. Recent reports show that the food pump market is projected to reach USD 1.2 billion by 2025, growing at a CAGR of 5.2%. This growth is driven by an increasing demand for efficiency and safety in food handling. Innovations such as smart sensors and automated controls are transforming how pumps operate. These advancements enhance not just productivity but also compliance with stringent safety regulations.

Efficiency is paramount. Using pumps that reduce energy consumption can lead to significant cost savings. However, many facilities overlook the importance of regular maintenance. Regular checks can prevent inefficiencies that lead to increased waste. Upgrading to more efficient models may seem costly initially, but the long-term benefits outweigh the investment.

Tips: Ensure regular pump maintenance. Monitor energy use closely. Embrace new technologies gradually to test their effectiveness. Some companies struggle with the adoption of innovations. Training staff can bridge this gap, helping them understand the benefits. Each step forward can lead to enhanced productivity and safety in operations. Keeping pace with market trends is essential for maintaining a competitive edge.

In the food processing industry, safety standards for transfer pumps are paramount. Regulations set by organizations like the FDA and NSF ensure that food handling complies with hygiene requirements. For instance, a recent report stated that 70% of food safety incidents stem from poor equipment maintenance. This highlights the importance of using pumps made from food-grade materials.

When selecting a food transfer pump, consider certifications. Look for pumps that meet FDA standards. These pumps must have resistances to corrosion and contamination. Moreover, equipment must undergo regular inspections. A regular inspection schedule can reduce risks and enhance operational efficiency.

Tip: Always conduct routine maintenance on your pumps. This avoids costly breakdowns. A critical aspect is checking seals and gaskets for wear. Replacing them regularly can prevent leaks and ensure safety. Neglecting these small parts can lead to bigger problems down the line. Ensure your team is trained in pump safety protocols to handle any issues.

Consumer demands for safety continue to rise. That means food transfer pumps must evolve. The industry faces challenges in maintaining compliance while maximizing efficiency. However, neglecting safety can have severe consequences. It's essential to commit to the highest standards in food transfer operations.

| Pump Model | Flow Rate (L/min) | Material | Max Pressure (bar) | Temperature Range (°C) | Certification |

|---|---|---|---|---|---|

| Model A | 50 | Stainless Steel | 10 | -10 to 90 | FDA, CE |

| Model B | 75 | Aluminum | 8 | 0 to 80 | NSF, ISO |

| Model C | 100 | Plastic | 6 | -5 to 70 | FDA, CE |

| Model D | 65 | Stainless Steel | 12 | -10 to 85 | ISO, GMP |

| Model E | 30 | Plastic | 5 | 0 to 60 | FDA, CE |

| Model F | 85 | Aluminum | 7 | -10 to 75 | NSF, ISO |

| Model G | 40 | Plastic | 4 | 0 to 50 | FDA, CE |

| Model H | 66 | Stainless Steel | 11 | -5 to 90 | ISO, GMP |

| Model I | 55 | Aluminum | 9 | -10 to 80 | FDA, CE |

| Model J | 90 | Plastic | 6 | 0 to 70 | NSF, ISO |

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.