Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the evolving landscape of industrial applications, the significance of high pressure slurry pumps cannot be overstated. As experts like Dr. Sarah Thompson, a renowned authority in fluid dynamics and pumping technology, have asserted, "The efficiency of high pressure slurry pumps is crucial for optimizing material transport in various sectors, from mining to wastewater treatment." With the growing demand for robust and efficient transport solutions, understanding the key features of high pressure slurry pumps becomes essential for businesses seeking to enhance their operational efficiencies.

In 2025, industry professionals must navigate a myriad of options when selecting a high pressure slurry pump that meets their specific needs. The market is inundated with innovations and advancements that cater to diverse industrial requirements, making a comprehensive buying guide indispensable. Key aspects such as pump materials, hydraulic design, and energy efficiency are critical factors that influence both performance and longevity.

This guide aims to elucidate the essential features and considerations for purchasing high pressure slurry pumps, ensuring that stakeholders make informed decisions tailored to their operational demands. By focusing on both the technology and practical implementation of these pumps, we can pave the way for improved productivity and sustainability in slurry handling processes.

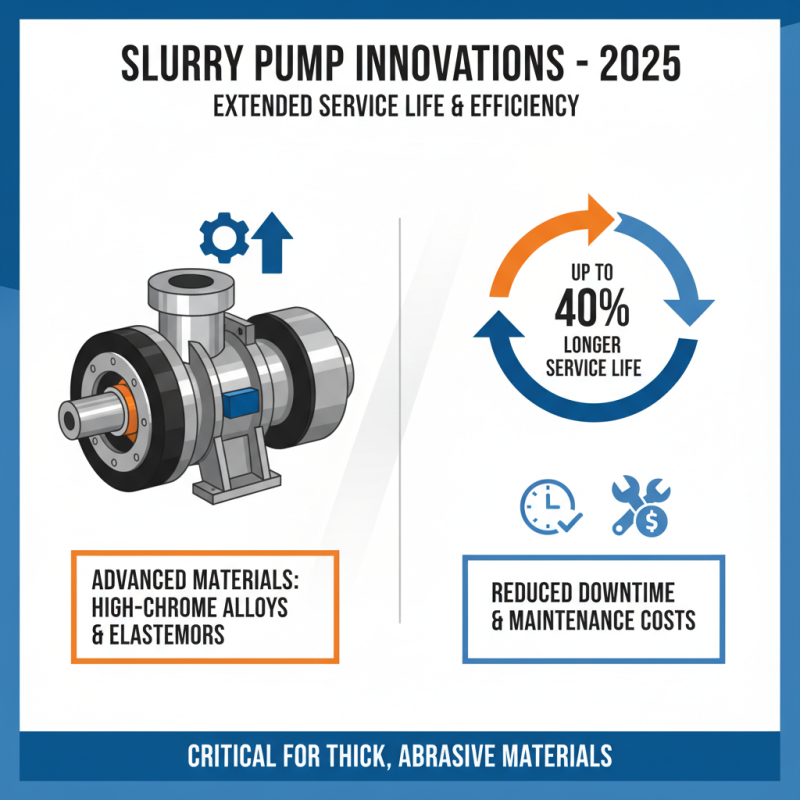

In 2025, the performance and efficiency of high pressure slurry pumps remain critical factors for industries dealing with thick, abrasive materials. One of the key features to look for is the pump’s material composition. Advanced materials such as high-chrome alloys and elastomers are increasingly favored for their resistance to wear and corrosion. According to a recent industry report by the Global Slurry Pump Market Analysis, pumps constructed from these materials can achieve a service life extended by up to 40%, thereby reducing downtime and maintenance costs significantly.

Another important feature is the pump design, which enhances operational efficiency and energy consumption. Innovations such as multi-stage configurations and adjustable impeller designs can significantly improve flow rates and pressure capabilities. Data indicates that high pressure slurry pumps that utilize these advanced designs can achieve up to 20% higher efficiency compared to traditional models. Furthermore, features like smart control systems and real-time monitoring provide operators with critical insights into performance, enabling proactive adjustments and ensuring optimal operation under varying conditions.

Overall, the integration of these advanced materials and innovative designs positions the high pressure slurry pumps of 2025 as essential tools for industries ranging from mining to wastewater treatment, where the handling of slurries demands unmatched reliability and efficiency.

When selecting high-pressure slurry pumps, it's essential to understand the different types available on the market. Primarily, these pumps can be categorized into two main types: centrifugal slurry pumps and positive displacement slurry pumps.

Centrifugal slurry pumps use a rotating impeller to enhance the velocity of the slurry. They are suitable for transporting mixtures with lower viscosity and are widely used in industries such as mining and construction. Positive displacement slurry pumps, on the other hand, operate by trapping a fixed amount of slurry and then forcing it into the discharge pipe. These pumps are ideal for handling thicker or more viscous slurries typically found in wastewater treatment and chemical processing.

Tips: When choosing a pump, consider the specific material properties of the slurry, including its density and viscosity, as these factors will significantly influence pump performance. Additionally, ensure that the pump's construction materials are suitable for the slurry’s chemical composition to avoid premature wear.

Another crucial aspect to consider is the pump's flow rate and pressure capabilities, as selecting the right specifications can drastically affect efficiency and operational costs. Understanding the application's unique requirements will guide you in making an informed decision, ensuring optimal performance in your slurry transport system.

When purchasing a high-pressure slurry pump, several key factors must be taken into consideration to ensure you select the right equipment for your specific needs. First and foremost, you should evaluate the pump's intended application, as different industries may require different designs and materials. For example, pumps used in mining applications often need to handle abrasive materials, which means selecting a pump with corrosion-resistant components and robust construction. Understanding the physical properties of the slurry, such as its viscosity and particle size, will also inform your choice and help predict pump performance.

Another critical aspect to consider is the pump's efficiency and energy consumption. High-efficiency models may have higher initial costs but can lead to significant savings in energy expenses over the long term. Moreover, consider the maintenance requirements and serviceability of the pump. A good design will allow for easy access to components for routine checks and repairs, reducing downtime and maintenance costs. Lastly, ensure that the pump's specifications such as flow rate, pressure rating, and material compatibility align well with your operational requirements, as this will ultimately impact its performance and lifespan.

| Model | Max Flow Rate (m³/h) | Max Pressure (bar) | Power (kW) | Weight (kg) | Key Features |

|---|---|---|---|---|---|

| Model A | 370 | 16 | 55 | 150 | High efficiency, wear-resistant materials |

| Model B | 450 | 20 | 75 | 200 | Variable speed drive, compact design |

| Model C | 500 | 25 | 90 | 250 | Multi-stage design, easy maintenance |

| Model D | 600 | 22 | 110 | 300 | Remote monitoring, high durability |

| Model E | 650 | 30 | 132 | 320 | Energy efficient, customizable options |

Maintaining high pressure slurry pumps is crucial for ensuring optimal performance and longevity. Regular maintenance checks can help identify potential issues before they escalate, reducing costly downtime and repairs. One essential tip is to inspect the pump's seals and gaskets frequently for wear and tears. Deterioration of these components can lead to leaks and inefficiency, so replacing them at the first sign of damage is vital.

Another important aspect of maintenance is monitoring the pump's operating temperature and pressure. Keeping an eye on these parameters allows you to catch abnormalities that might indicate a deeper issue, such as excessive friction or blockages in the pipeline. If temperatures rise above normal levels, it may require immediate attention to prevent severe damage to the pump.

Additionally, regular lubrication of moving parts cannot be overstated. Proper lubrication reduces friction among components and ensures smooth operation. Always use the recommended lubricant and adhere to the manufacturer's guidelines for intervals. By following these tips, operators can extend the life of their high pressure slurry pumps and maintain efficient operation in demanding environments.

In 2025, the slurry pump market continues to show robust growth, with industry projections indicating an expansion driven by increasing demand in sectors such as mining, construction, and wastewater management. According to a recent market analysis report, the slurry pump segment is expected to grow at a compound annual growth rate (CAGR) of 4.5%, reaching an estimated value of $4.7 billion by the end of the forecast period. This growth is largely attributed to the rising need for efficient and durable pumping solutions capable of handling abrasive and viscous materials.

When considering the top brands and models in 2025, several key features stand out in high-pressure slurry pumps. Models with enhanced wear-resistant materials, such as high-chrome alloys and advanced polymer linings, are increasingly favored for their longevity in harsh environments. Furthermore, innovative designs that facilitate easy maintenance and lower operational costs are in high demand. The latest report highlights that pumps with tiered performance capabilities, allowing for customizable pressure and flow rates according to specific applications, have gained prominence among industrial users. As companies seek to optimize efficiency and lower downtime, these advanced features position certain brands and models at the forefront of the slurry pump market this year.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.