Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the realm of fluid management, the significance of effective filtration cannot be overstated, particularly when it comes to transfer pump filters. According to a report by the Global Filtration Industry, the demand for filtration systems in various industrial applications is projected to reach $50 billion by 2025, highlighting the critical role that advanced filtering technologies, such as transfer pump filters, play in enhancing operational efficiency and ensuring fluid purity.

These filters are specifically designed to operate seamlessly within pumping systems, preventing contaminants from compromising fluid integrity and performance. As industries are increasingly faced with stringent regulatory standards and the need for sustainable practices, understanding the unique features and benefits of transfer pump filters becomes essential for optimizing fluid management strategies and safeguarding equipment health.

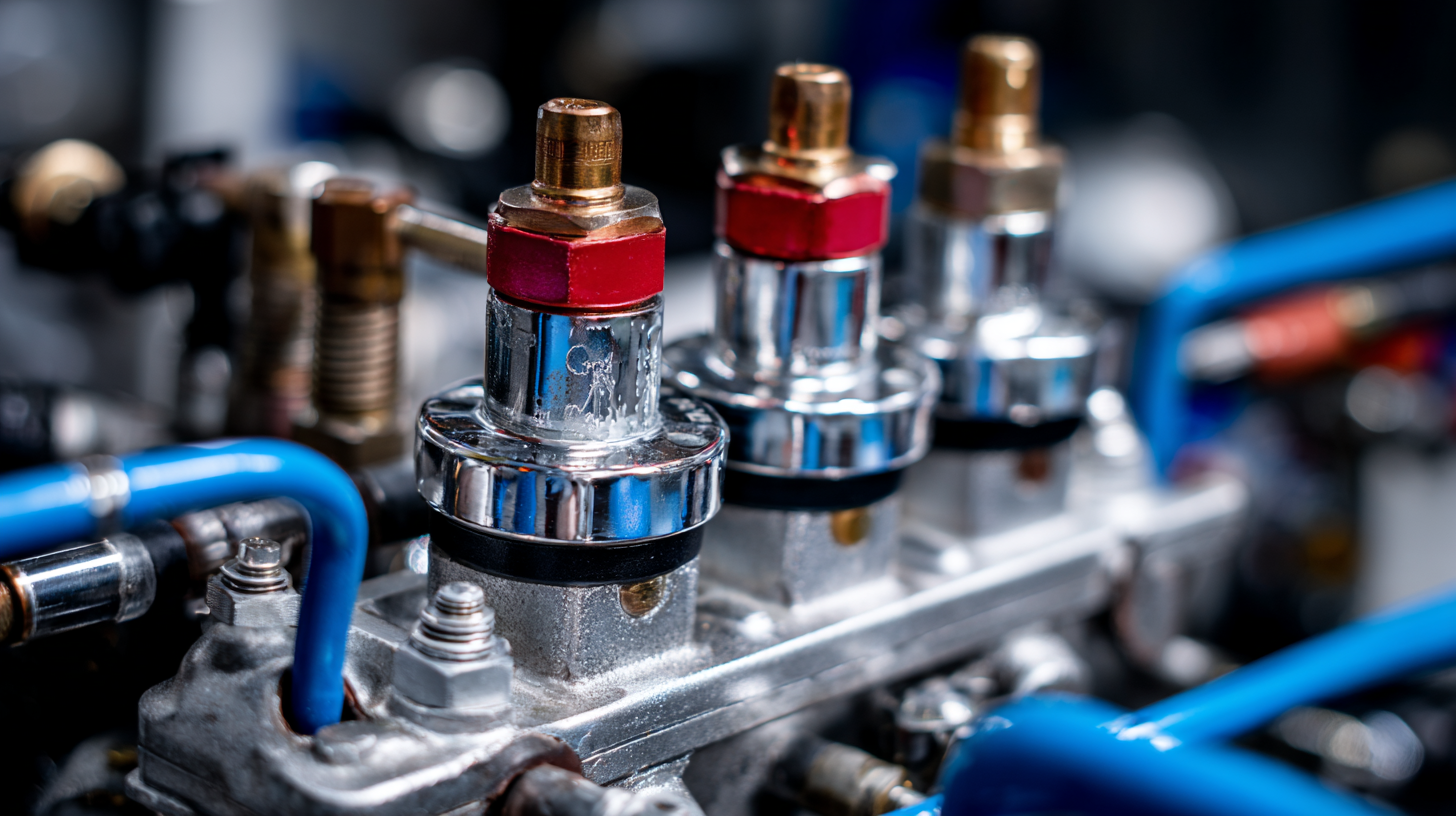

Transfer pump filters play a crucial role in fluid management systems, ensuring the purity and efficiency of the fluids being transported. Key components of these filters include filter media, housings, and sealing mechanisms. The filter media, often made from materials like pleated paper or stainless steel, captures contaminants and particulates, safeguarding the transfer pump's performance. The housing provides structural integrity while also enabling easy maintenance and replacement routines.

When selecting transfer pump filters, it’s essential to consider the materials used in the filter media based on the type of fluid being managed. For high-viscosity fluids, opt for filters designed to withstand greater pressure. Additionally, ensure that the sealing mechanisms are robust and compatible with the pump to prevent leaks and maintain optimal pressure.

Tip: Regularly check and replace your transfer pump filters to maintain efficiency and prolong the lifespan of your pump. Another vital consideration is to select a filter that matches the flow rate requirements of your system to avoid unnecessary strain on the pump, which can lead to costly repairs.

This chart illustrates the performance metrics of key components in transfer pump filters used for fluid management. Each component's effectiveness is quantified, showcasing the filtration efficiency, flow rate, pressure drop, filter media durability, and cost efficiency.

Transfer pump filters play a crucial role in fluid management, especially in clinical environments where the safe delivery of intravenous (IV) fluids is paramount. These filters are designed to remove particulate matter, bacteria, and other contaminants, ensuring the integrity of the infusion therapy. Recent advancements in IV therapy highlight the importance of these filters, as reports indicate that up to 18% of IV-related complications arise from contaminants and poor fluid management. Incorporating transfer pump filters not only enhances patient safety but also reduces the risk of hospital readmissions due to related complications.

Tips: Ensure that transfer pump filters are maintained and replaced regularly to maximize their efficacy. Training healthcare staff on the proper use of these filters can also mitigate risks associated with fluid management.

Using transfer pump filters offers several advantages. They significantly improve fluid purity by effectively filtering out microplastics and particulates, which, as recent studies indicate, have been identified in intravenous fluid delivery systems. This not only protects patients from potential harm but also supports hospitals in adhering to strict safety regulations. Furthermore, the incorporation of advanced filtration technology allows for seamless integration into various infusion systems, ensuring that fluid delivery remains uninterrupted while maintaining high standards of care.

Tips: Regular audits of filter performance can provide valuable insights into their effectiveness, allowing for timely upgrades and maintenance. Collaborating with clinical staff to understand their experiences with these filters can also foster improvements in patient care protocols.

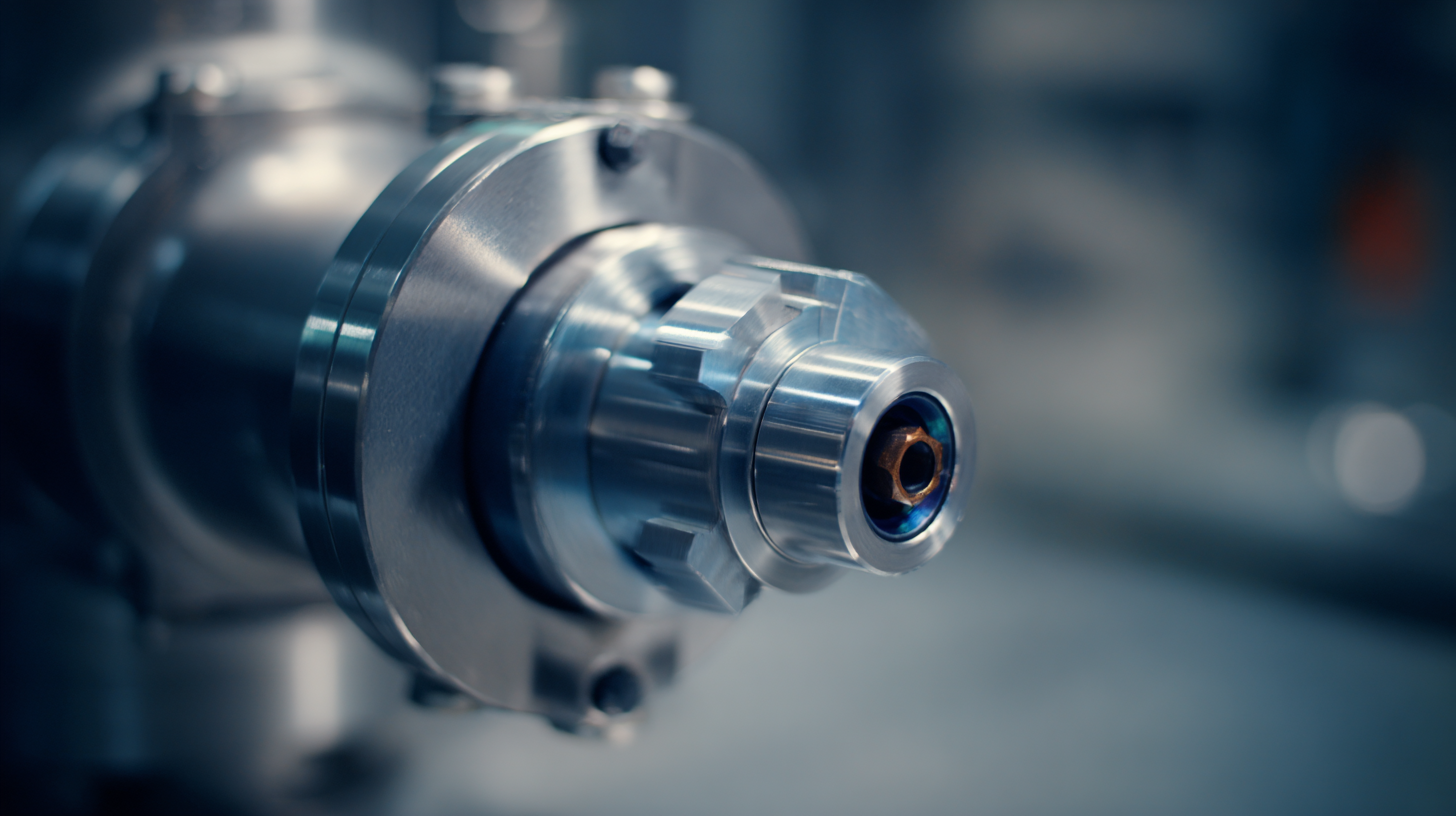

Transfer pump filters play a crucial role across various industries by ensuring the purity and efficiency of fluid management systems. In the chemical manufacturing sector, these filters help remove particulates and contaminants from liquids, thus safeguarding equipment and maintaining product integrity. The energy sector also relies on transfer pump filters to manage the transportation of fuels and lubricants, ensuring that machinery operates smoothly and efficiently while extending the lifespan of vital components.

In the food and beverage industry, transfer pump filters are essential for maintaining hygiene and compliance with safety regulations. They prevent unwanted particles from entering the production line, thus ensuring that the final products meet health standards. Additionally, in pharmaceuticals, these filters are indispensable for maintaining the sterility of liquid medications and preventing contamination during the transfer processes. As industries continue to evolve, the versatility of transfer pump filters will remain a key factor in enhancing operational efficiency and safety in fluid management.

When selecting the right transfer pump filter for your needs, it’s essential to consider several key factors that can significantly affect performance and efficiency. First, evaluate the type of fluid you'll be transferring. Different fluids, whether viscous liquids or abrasive substances, require specific filter designs to ensure optimal flow and prevent clogging. For example, a filter suited for water may not hold up well against heavy oils, so selecting a filter that matches your specific fluid characteristics is crucial.

Another important aspect to consider is the filter’s micron rating, which indicates the size of particles the filter can capture. If you are dealing with particularly dirty fluids or environments, a filter with a lower micron rating may be necessary to ensure contaminants are effectively removed. Additionally, take into account the flow rate and pressure requirements of your system. A filter that can maintain the necessary flow without compromising pressure is vital for efficient operation. By carefully assessing these factors, you can choose a transfer pump filter that meets your unique fluid management needs, leading to improved efficiency and longevity of your equipment.

Effective maintenance of transfer pump filters is crucial for ensuring their optimal performance in fluid management systems. According to a report from the Fluid Power Journal, regular maintenance can enhance the efficiency of transfer pumps by up to 30%. This efficiency gain not only results in improved fluid flow but also prolongs the lifespan of the equipment, leading to reduced operational costs.

One key maintenance tip is to implement a scheduled cleaning regimen. Filters should be inspected and cleaned every 500 hours of operation or according to the manufacturer's guidelines. Additionally, replacing filters at regular intervals, which the Parker Hannifin Corporation suggests should be done every 1000 hours, can prevent clogging and ensure contaminants do not enter the pump system. Monitoring differential pressure across the filter can also provide insights into when replacement or servicing is needed, as a rise in pressure can indicate an overload of particulates that could impair performance.

Incorporating these maintenance strategies not only safeguards equipment but also aligns with best practices in fluid management, contributing to overall system reliability and efficiency.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.