Universal Pumping | High Pressure Pumps

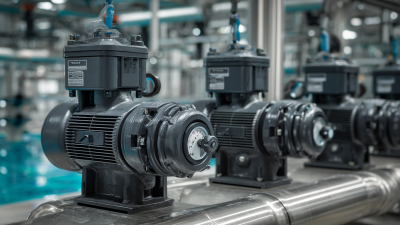

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the highly competitive landscape of modern manufacturing, innovative technologies have become essential to meet increasing production demands and enhance product quality. The diaphragm press, a pivotal development in pressing technology, offers remarkable advantages, including improved precision, higher energy efficiency, and reduced operational costs. According to a recent industry report by Smith & Associates, the market for diaphragm presses is projected to grow by 15% annually over the next five years, driven by rising demand in sectors such as automotive and aerospace manufacturing. This surge is attributed to the diaphragm press's ability to produce complex shapes with minimal material wastage, thus promoting sustainable manufacturing practices. By unlocking the potential of diaphragm press technology, manufacturers can not only optimize their production capabilities but also stay ahead in an ever-evolving industry landscape.

Diaphragm press technology is a pivotal advancement in modern manufacturing, allowing for enhanced precision and efficiency. This technology utilizes a flexible diaphragm to evenly distribute pressure across materials during the forming process. By minimizing localized stresses, diaphragm presses can produce intricate components with superior surface finishes and dimensional accuracy. This ability to work with a variety of materials, including metals, plastics, and composites, makes diaphragm press technology versatile and applicable across multiple industries, including aerospace, automotive, and consumer products.

Understanding the fundamentals of diaphragm press technology begins with its operational mechanics. The diaphragm, typically made of elastomeric or flexible materials, responds to hydraulic or mechanical forces, conforming to the shape of the die and the material being processed. This process not only enhances the forming capabilities but also reduces wear and tear on the tooling, ultimately extending the lifespan of manufacturing equipment.

Furthermore, the technology supports batch production and can be easily integrated into automated manufacturing systems, leading to increased productivity and reduced manufacturing costs, thus unlocking its potential in contemporary manufacturing scenarios.

Diaphragm press technology has emerged as a revolutionary advancement in modern manufacturing, offering several key advantages over traditional pressing methods. One of the most significant benefits is its ability to provide uniform pressure distribution, which results in enhanced material quality and reduced defects. This consistent application of pressure minimizes the risk of material deformation and allows for the production of complex shapes with precision, empowering manufacturers to innovate with their designs.

Tip: When considering diaphragm press technology for your manufacturing process, ensure that your design requirements align with the specific capabilities of the diaphragm press, particularly in terms of pressure range and material compatibility.

Moreover, diaphragm presses tend to be more energy-efficient compared to their traditional counterparts. The technology often requires less power to operate while achieving similar or better results, leading to reduced operational costs. This efficiency not only benefits the bottom line but also aligns with the growing emphasis on sustainability in manufacturing practices.

Tip: Regular maintenance and calibration of diaphragm presses can further enhance their efficiency and longevity, ensuring optimal performance throughout the production cycle.

The integration of digital solutions in diaphragm press operations marks a transformative era in modern manufacturing. With the adoption of Industry 4.0 principles, diaphragm presses have evolved to leverage advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. According to a report by MarketsandMarkets, the global smart manufacturing market is projected to reach $515 billion by 2025, with a significant portion of that growth attributed to the adoption of digital solutions in traditional manufacturing processes.

Utilizing digital tools, manufacturers can enhance operational efficiency and product quality. Real-time monitoring through connected devices allows for predictive maintenance, reducing downtime by up to 30%. Additionally, machine learning algorithms can optimize pressing parameters, ensuring consistent product output while minimizing material waste. A study from McKinsey estimates that digitization in manufacturing could unlock up to $3.7 trillion in economic value, showcasing the potential of integrating smart technologies within diaphragm press operations. By embracing these innovations, manufacturers can not only boost productivity but also meet the increasingly dynamic demands of the market.

Diaphragm press technology

has emerged as a powerful tool in modern manufacturing, enabling high precision and efficiency in the production process. One notable case study involves a leading automotive manufacturer that implemented diaphragm presses to streamline their stamping operations. By employing these presses, the company was able to reduce cycle times significantly while maintaining exceptional part quality. The uniform pressure distribution offered by the diaphragm design minimized defects such as warping and misalignment, ultimately enhancing productivity and cost-effectiveness.

Another successful implementation can be seen in the aerospace sector, where a major aircraft parts supplier adopted diaphragm presses for composite material fabrication. This technology allowed for the uniform application of pressure across intricate molds, resulting in superior mechanical properties and structural integrity of the components produced. The supplier noted a remarkable decrease in waste material and an increase in production output, showcasing the adaptability and advantages of diaphragm press technology in specialized manufacturing environments. Through these case studies, it is evident that diaphragm press technology not only optimizes current processes but also opens new avenues for innovation in various industries.

The diaphragm press technology is experiencing a transformative phase, driven by innovations that enhance efficiency and precision in modern manufacturing. Recent studies indicate that the global diaphragm press market is projected to grow at a CAGR of 5.4% from 2022 to 2027, highlighting the increasing adoption of this technology across various industries such as aerospace, automotive, and electronics. Key advancements include the integration of automation and smart technology, enabling real-time monitoring and quality control that significantly reduce production times and costs.

Tip: To leverage the benefits of diaphragm press technology, manufacturers should consider investing in advanced training for their workforce to ensure the seamless integration of these innovations into existing processes.

Emerging trends also point towards the sustainability aspect of diaphragm presses, with many manufacturers focusing on eco-friendly materials and energy-efficient operations. Companies that adopt this technology not only enhance their production capabilities but also align with global sustainability goals. The shift towards greener manufacturing practices is supported by a report from the International Energy Agency, which shows that energy-efficient technologies can reduce emissions by up to 20% in manufacturing processes.

Tip: Evaluate your current manufacturing processes to identify areas where diaphragm press technology can replace traditional methods, ultimately contributing to both operational efficiency and sustainability objectives.

| Application Area | Innovation | Benefits | Future Trends |

|---|---|---|---|

| Automotive Production | Integration with Smart Sensors | Increased Precision and Reduced Scrap | Greater Automation and AI Involvement |

| Consumer Electronics | Advanced Material Usage | Lightweight Components and Durability | Sustainable Manufacturing Practices |

| Aerospace Engineering | 3D Printing Integration | Complex Geometries and Weight Reduction | Hybrid Manufacturing Techniques |

| Medical Devices | Micro-press Technology | Enhanced Accuracy in Component Fabrication | Miniaturization of Devices |

| Renewable Energy | Innovative Pressure Forming Techniques | Increased Efficiency in Component Production | Focus on Energy-efficient Manufacturing |

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.