Universal Pumping | High Pressure Pumps

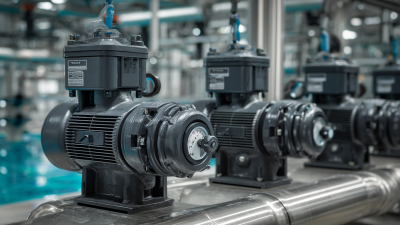

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

As the 138th Canton Fair approaches in 2025, the spotlight on waste pump innovations becomes increasingly pertinent amidst the evolving landscape of waste management solutions. The global waste management market is projected to reach USD 2 trillion by 2025, with waste pumps playing a crucial role in enhancing efficiency and sustainability within the sector.

Recent studies indicate that innovative waste pump technologies can improve operational efficiency by up to 40%, significantly reducing downtime and maintenance costs. With the growing emphasis on environmental responsibility and the adoption of smart technology, the demand for advanced waste pump systems is expected to rise. This trend underscores the importance of the Canton Fair as a pivotal platform for showcasing cutting-edge waste pump solutions, providing industry stakeholders with valuable insights into the latest advancements and future directions in waste management technology.

Recent studies indicate that innovative waste pump technologies can improve operational efficiency by up to 40%, significantly reducing downtime and maintenance costs. With the growing emphasis on environmental responsibility and the adoption of smart technology, the demand for advanced waste pump systems is expected to rise. This trend underscores the importance of the Canton Fair as a pivotal platform for showcasing cutting-edge waste pump solutions, providing industry stakeholders with valuable insights into the latest advancements and future directions in waste management technology.

At the 138th Canton Fair, innovative technologies in waste pump design took center stage, reflecting the industry's commitment to sustainability and efficiency. Exhibitors showcased state-of-the-art waste pumps that incorporate smart sensors, energy-efficient motors, and advanced materials designed to improve performance while reducing environmental impact. Many models feature real-time monitoring capabilities, allowing for proactive maintenance and minimizing downtime, which is crucial for businesses aiming to enhance operational efficiency.

Tips: When considering a waste pump for your operations, look for models that offer smart technology integration. Features such as IoT connectivity can provide invaluable data to optimize performance and predict maintenance needs. Additionally, prioritize energy-efficient designs, as they not only reduce costs but also align your business practices with sustainability goals.

The exploration of these innovations at the fair highlights the shifting landscape of waste management solutions. With an increasing emphasis on reducing carbon footprints, manufacturers are pushing the boundaries of technology to develop more reliable and eco-friendly waste pumps. Attendees noted the importance of investing in future-proof designs that can adapt to the evolving needs of industries and environmental regulations.

The 138th Canton Fair in 2025 showcases remarkable advancements in waste pump technology, with a focus on enhancing efficiency and sustainability. As industries strive to reduce their environmental footprint, innovative waste pumps are designed with cutting-edge materials and engineering that not only improve operational performance but also minimize energy consumption. This emphasis on efficiency is pivotal in meeting regulatory demands while maximizing productivity within various sectors.

Sustainability has emerged as a key driver in waste pump design, with manufacturers adopting eco-friendly practices throughout the production process. From utilizing recycled materials to implementing energy-efficient motors, the new generation of waste pumps is setting a benchmark for responsible manufacturing. Furthermore, advancements in smart technology allow for better monitoring and control of waste management systems, enabling real-time adjustments that can lead to significant resource savings. These emerging trends at the Canton Fair reflect a broader commitment within the industry to innovate sustainably and enhance the overall efficacy of waste management solutions.

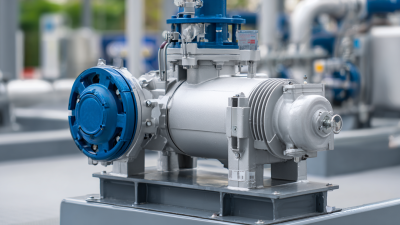

At the 138th Canton Fair in 2025, global stakeholders in the waste pump industry congregated to showcase and examine the latest advancements. A comparative analysis of manufacturers from various countries revealed significant trends shaping the market. Leading companies demonstrated innovations that enhance efficiency and sustainability, focusing on electric and solar-powered waste pumps that cater to the growing demand for eco-friendly solutions.

During the fair, exhibitors highlighted the importance of durability and ease of maintenance in their products. Notably, manufacturers from Europe and Asia presented state-of-the-art designs that integrate smart technology, allowing for real-time monitoring and data analysis. This trend not only optimizes operational performance but also aids in predictive maintenance, reducing downtime and overall costs for end-users. By sharing insights and fostering collaborations, the Canton Fair serves as a pivotal platform for driving progress and addressing challenges within the waste pump sector.

The 138th Canton Fair in 2025 serves as a pivotal event for the waste pump industry, bringing together professionals, innovators, and stakeholders eager to forge meaningful connections. Networking opportunities abound as attendees engage in discussions that can lead to strategic partnerships and collaborations. Participants can explore innovative solutions and share insights that drive industry advancements, ultimately enhancing operational efficiencies and sustainability in waste management.

In addition to formal networking sessions, the fair also features collaborative initiatives designed to foster dialogue between manufacturers, suppliers, and environmental experts. Workshops and panel discussions will focus on emerging trends, new technologies, and regulatory challenges, providing a platform for participants to brainstorm and develop joint ventures. This collaborative environment encourages companies to leverage each other’s strengths, paving the way for groundbreaking innovations in waste pump design and functionality. By engaging in these initiatives, businesses can set the stage for a more sustainable future in waste management.

| Innovation Type | Description | Application Area | Recent Trends | Collaborations |

|---|---|---|---|---|

| Smart Waste Pumps | Pumps equipped with IoT sensors for monitoring performance | Municipal Waste Management | Increased automation and remote monitoring | Partnerships with tech companies |

| Eco-Friendly Pumps | Pumps made from recyclable materials | Industrial Waste Processing | Sustainability initiatives gaining momentum | Collaborative research with universities |

| High-Efficiency Pumps | Pumps designed to minimize energy consumption | Agricultural and Irrigation Systems | Focus on energy savings and cost reduction | Joint ventures with energy firms |

| Modular Pumps | Pumps that can be customized and expanded | Construction Sites | Adoption of flexible design for varying needs | Collaborations with construction companies |

At the 138th Canton Fair 2025, industry leaders are set to gather to address the pressing challenges facing waste management today. With the ongoing push towards sustainability, future-proofing waste management techniques will be a key focus. Innovations in waste pump technology are at the forefront, highlighting how new advancements can improve efficiency and minimize environmental impact. Industry experts will share their insights on integrating cutting-edge solutions to transform waste management practices, ensuring that companies can adapt to evolving regulatory standards and consumer expectations.

The recent Australian promotional event for the Canton Fair has emphasized the growing importance of international collaboration in waste management strategies. Discussions at this forum underscored the necessity for Chinese enterprises to explore overseas markets, particularly in Australia. This exploration is pivotal as companies seek to share knowledge and best practices, ultimately striving for more sustainable waste management solutions. By leveraging insights from industry leaders, participants aim to enhance their approaches to waste management, ensuring that they remain competitive and environmentally responsible in the global arena.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.