Universal Pumping | High Pressure Pumps

High Pressure Pumps for Difficult to Pump Slurry, Sludge, and Food Waste.

In the realm of fluid handling, the selection of the right pumping system can dramatically affect operational efficiency and reliability. Among the various types of pumps available, the positive displacement pump stands out for its ability to deliver consistent flow regardless of changes in pressure. Industry expert Dr. John Smith, a renowned mechanical engineer based in fluid dynamics, emphasizes the importance of understanding pump selection: "A positive displacement pump not only ensures accurate fluid transfer but also adapts effortlessly to varying process conditions."

As businesses strive to optimize their fluid handling processes, choosing the appropriate technology becomes imperative. Positive displacement pumps are particularly suited for applications requiring precision and reliability, especially in industries such as chemical processing, food and beverage, and oil and gas. The design of these pumps enables them to move a fixed amount of fluid with each cycle, making them ideal for handling viscous and shear-sensitive fluids, where uniform flow is critical.

The advantages of implementing a positive displacement pump extend beyond mere functionality. By minimizing the risk of leaks and maintaining energy efficiency, these pumps contribute to sustainable practices within various sectors. In this discussion, we will delve deeper into the benefits that positive displacement pumps offer and why they should be at the forefront of your fluid handling solutions.

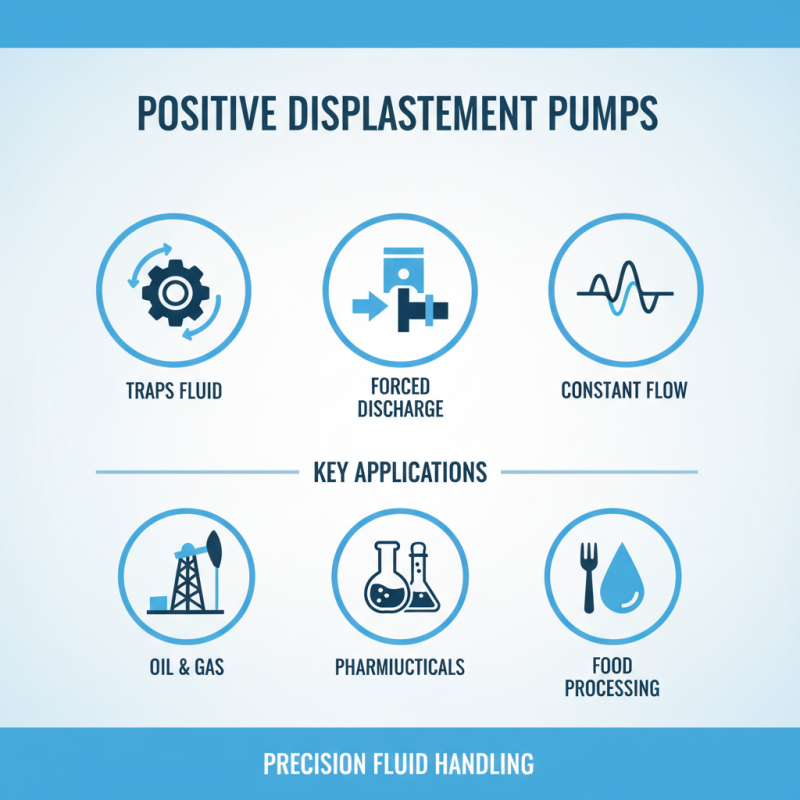

Positive displacement pumps (PDPs) operate by trapping a fixed amount of fluid and forcing that volume into the discharge pipe, making them exceptionally reliable for a variety of fluid handling needs. Unlike centrifugal pumps, which rely on high-speed impellers to create flow, PDPs generate pressure through the direct displacement of fluid. This mechanism allows them to handle highly viscous fluids and provide consistent flow rates even in challenging applications, such as in the food and beverage industry where viscosity can vary significantly. According to a recent industry report by MarketsandMarkets, the positive displacement pump market is projected to grow at a CAGR of 4.6% from 2022 to 2027, indicating a strong preference for their utilization across various sectors.

When considering positive displacement pumps, it’s essential to take into account how they are operated under various conditions. They can handle a wide range of pressures and operate effectively with both Newtonian and non-Newtonian fluids. However, it’s crucial to note that they should not be used in applications where the flow rate needs to significantly change, as the fixed discharge may lead to system pressure build-up. Tips: Always consult the manufacturer's specifications when selecting a PDP for your application to ensure compatibility with your fluid type and process requirements.

Moreover, maintenance and regular inspection play a vital role in extending the lifespan of positive displacement pumps. Due to their design, certain components, such as seals and internal gears, can wear down over time. According to the Hydraulic Institute, proper maintenance can lead to a 20-30% increase in operational efficiency. Tips: Implement a maintenance schedule and routinely check for signs of wear to avoid unexpected downtimes and costly repairs.

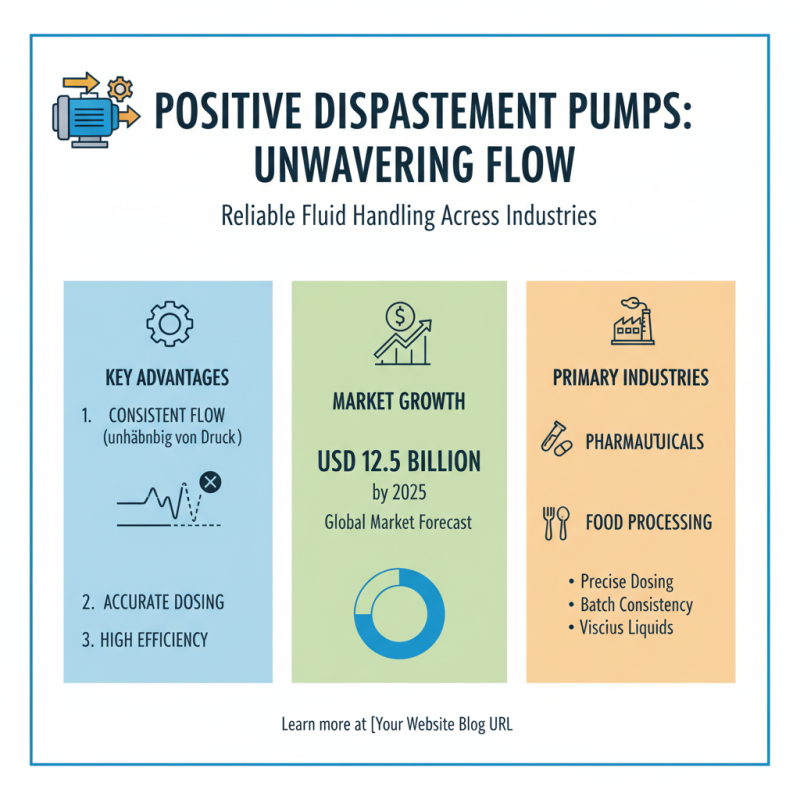

Positive displacement pumps are increasingly recognized for their advantages in fluid handling applications across various industries. One of the key benefits is their ability to deliver a consistent flow rate regardless of changes in pressure. According to a report by the Global Positive Displacement Pump Market, expected to reach USD 12.5 billion by 2025, this reliability makes them ideal for applications requiring precise dosing, such as in the pharmaceutical and food processing industries.

Moreover, positive displacement pumps excel in handling highly viscous fluids and slurries. Unlike centrifugal pumps, they create a vacuum that draws in fluid and forces it out in a continuous stream, which minimizes fluid shear and preserves product integrity. Research indicates that in industries dealing with high-viscosity materials, positive displacement pumps can achieve efficiencies of 90% or higher. This capability not only enhances process efficiency but also leads to reduced operational costs, making them a cost-effective solution for fluid transfer challenges.

Positive displacement pumps play a critical role in various industries due to their ability to handle a wide range of fluids, including viscous and abrasive materials. These pumps operate by trapping a fixed amount of fluid and forcing it through the discharge pipe, ensuring consistent flow rates regardless of pressure changes. This characteristic makes them ideal for applications in sectors such as oil and gas, pharmaceuticals, and food processing, where precise control over fluid handling is essential.

In the water and wastewater treatment industry, the demand for positive displacement pumps is particularly notable. As the global water and wastewater pumps market is projected to grow significantly, reaching $30.61 billion by 2032, the adoption of positive displacement pumps will likely increase. Their efficiency in transferring sludge, managing wastewater, and ensuring reliable service in treatment facilities makes them a preferred choice among engineers and operators. This trend reflects the industry's push towards optimizing performance and longevity in fluid handling systems.

When selecting a positive displacement pump for your fluid handling needs, there are several key considerations to keep in mind. First, assess the viscosity and temperature of the fluid being pumped. Positive displacement pumps are particularly effective for high-viscosity fluids, as they can maintain a consistent flow rate regardless of pressure fluctuations. Additionally, understanding the operational environment—such as potential corrosive substances or external temperatures—will help you choose a pump that can withstand these conditions.

Tips: Always check the manufacturer's specifications for the pump's compatibility with your specific fluids. This includes examining material construction to ensure it won't react adversely with your fluid. Moreover, remember to evaluate the required flow rate and pressure capabilities; selecting a pump that exceeds your operational requirements is generally a wise investment for future scalability.

Another important factor to consider is the pump's maintenance needs. Some positive displacement pumps require more upkeep than others, which can affect the overall efficiency and longevity of the system. Opting for pumps with easy access to service points can minimize downtime and maintenance costs, ensuring a more reliable operation.

Tips: Look for designs that allow for quick changes of seals and check the availability of spare parts. Ensuring that your team is trained on proper maintenance techniques can also greatly enhance pump performance over time.

| Feature | Description | Advantages | Common Applications |

|---|---|---|---|

| Flow Rate | Consistent flow regardless of pressure changes | Reliable and predictable performance | Chemical processing, food & beverage |

| Viscosity Handling | Capable of handling thick and viscous fluids | Suitable for a wider range of fluids | Paints, inks, oils |

| Maintenance | May require regular maintenance but generally robust | Durable with a long service life | Hydraulic systems, wastewater management |

| Self-Priming | Can draw fluid through suction without external assistance | Easy to install and operate | Water treatment, fuel transfer |

| Pressure Variation | Maintains performance even with pressure fluctuations | Improved system efficiency | Oil and gas, pharmaceutical processes |

Positive displacement pumps are renowned for their robustness and efficiency, but understanding their maintenance and longevity is crucial for optimizing fluid handling operations. According to a report by the Hydraulic Institute, proper maintenance practices can extend the service life of these pumps by as much as 30%. Regular inspection of components such as seals and bearings can prevent unexpected downtimes and costly repairs, ensuring that the pump operates within its designed parameters.

Moreover, positive displacement pumps are often designed with ease of maintenance in mind. Many manufacturers advocate for a scheduled maintenance protocol that includes routine checks and timely replacements of wear parts. Industry data suggests that improper maintenance can lead to a reduction in pump efficiency by up to 20%, directly impacting operational costs. By investing in a proactive maintenance strategy, users can not only enhance the longevity of their pumps but also improve overall system reliability, leading to more sustainable and efficient fluid handling solutions.

Universal Pumping

625 Apache Trail

Woodstock, GA 30189

Mon - Fri | 9:00 AM - 5:00 PM

Universal Pumping is staffed with industry professionals with 20-45 years experience with high pressure pumping systems. We represent only the “elite producers” in pump manufacturing: Britain’s EMS and Germany’s EMMERICH. Our engineering and manufacturing approach is conservative, and we do not use “guess work” in the design or sales of our pumping and filtration equipment.